Technical Assignments

The first technical

assignment focuses on the construction site’s existing conditions. The assignment covers the delivery system for

the project, a summary schedule, a summary of the systems being installed in

the building, an overall cost and the relative costs per square foot. The assignment continues on to explore the

project site plan, the local conditions for construction and summary of the

local market, and some more detailed information concerning the client and their

particular needs.

Existing

Construction Conditions

·

Project Schedule Summary pdf

·

Building Systems Summary pdf

Summary

Memo

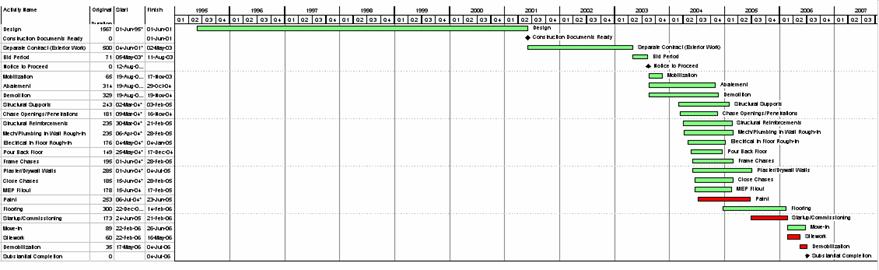

The following report is a summary of the overall project. The summary includes the way the project is

being delivered and the structure of the project relationships. There is an overview schedule with a

narrative to give a rough idea of the order of activities. The report also includes two preliminary

estimates using basic estimating methods to compare with the actual contract

cost. The report includes a site plan of

the existing site conditions and some temporary facilities. There is a review of the local construction

methods and conditions. Last, but most

important, there is an overview of the owner’s information and key values while

building the project.

The Smithsonian Institution Patent Office

Building is a very unique project.

Located in downtown DC, it takes up two square city blocks. The project was delivered as a traditional

Design-Bid-Build project with a CM agency to help oversee construction. The method seemed very appropriate based on

the owner’s experience and the unique demands of the project.

The

schedule depicts the long design time as well as the congestion the project

will feel due to overlap of trades when construction gets into full swing. The site is very tight, being in the center

of the city. Also, the courtyard poses

several issues due to the lack of access through the building. The building has a wide variety of building

systems, highlighted by its existing structurally arched masonry and the use of

the chimneys as mechanical chases.

The

estimates used to find cost information on the project appeared to be very

inaccurate due to the unique constraints of the project. The actual cost per square foot was much

higher than the estimates bore out. The

local construction conditions in DC favor concrete construction, which will be

used in the courtyard. Also, though the

project does little recycling, many of the historical materials in the building

will be restored and reused. Though the

storage of the materials will lead to further congestion.

Smithsonian

Institution is a unique client who has many attributes of a government agency,

however they tend to favor higher end work and finishes. The historical nature of the building is of

utmost importance to the owner, creating some unique situations and opportunities. The key interests of the owner lay in timely

completion due to the significance of the opening date, the 170th birthday of

the building and the 4th of July. Also, the

level of quality expected is very high.

All in all, the project is very complex and unique.

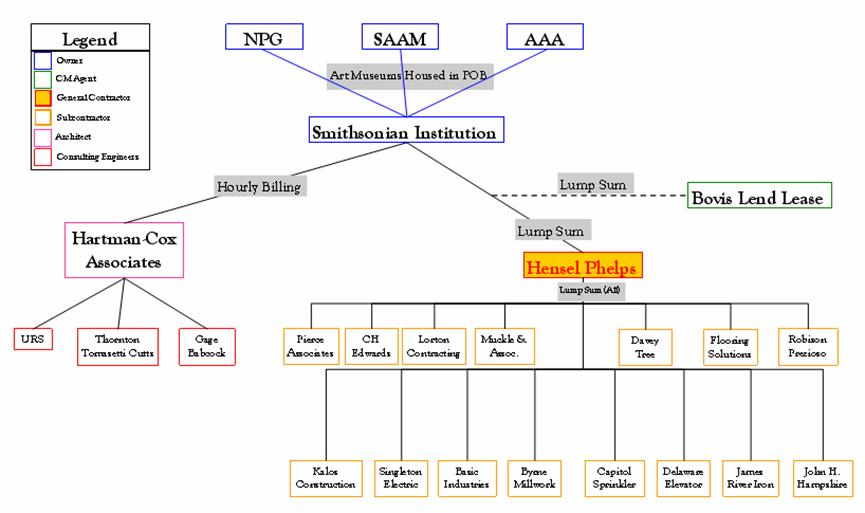

The

project is being delivered using a Traditional Design-Bid-Build method with a

CM agent. The owner, Smithsonian

Institution (SI), is experienced in construction. They have three separate museums being housed

within the Patent Office Building and each has very specific requirements for

the space they will occupy. SI has spent

a great deal of time in design tailoring the design to accommodate each

museum. The traditional method is

advantageous when the owner is experienced and has very set ideas about the

design of the building. Also, time was

not a critical issue when the project began, having several years to develop

the design and revise it before sending it out for bid. SI also chose to use a CM agent to assist in

the construction process. The CM agent

assists in the preconstruction phases to bring out constructability issues. With the considerable size and high quality

finishes required SI was glad to have someone else helping to monitor the

project, looking for problems and other areas of concern.

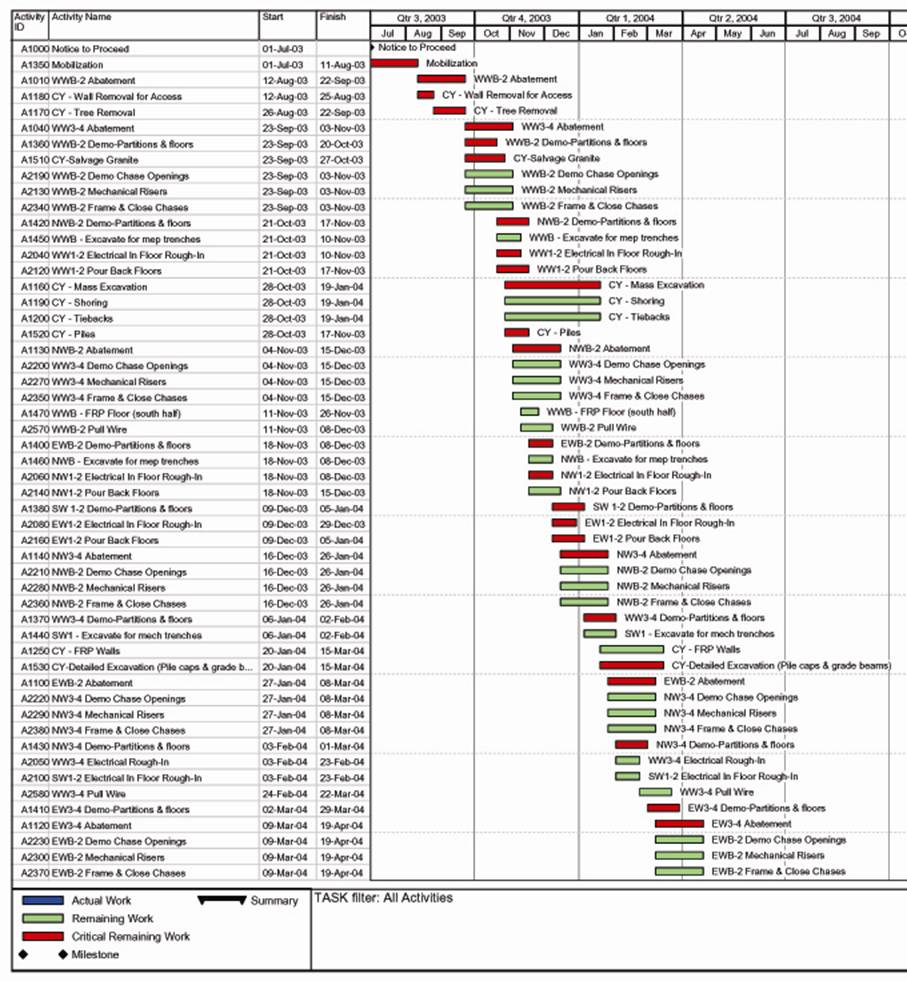

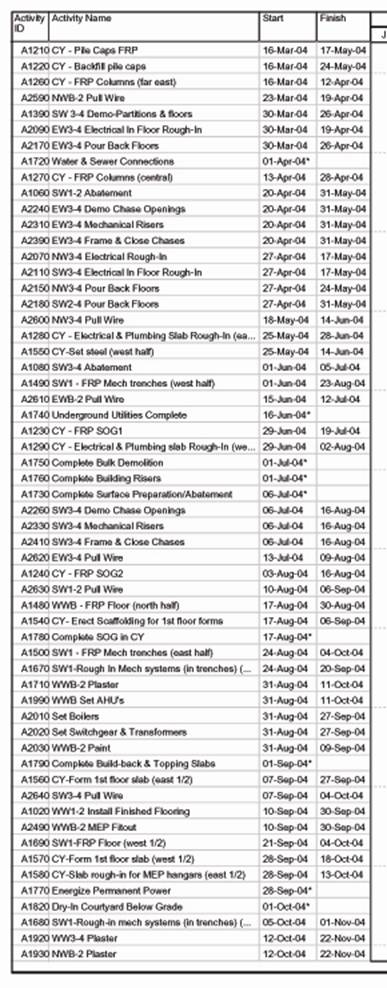

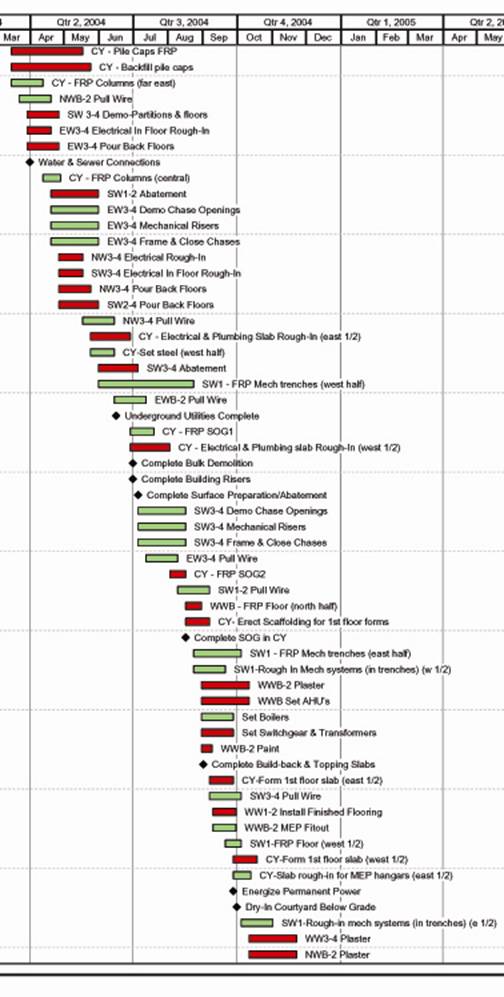

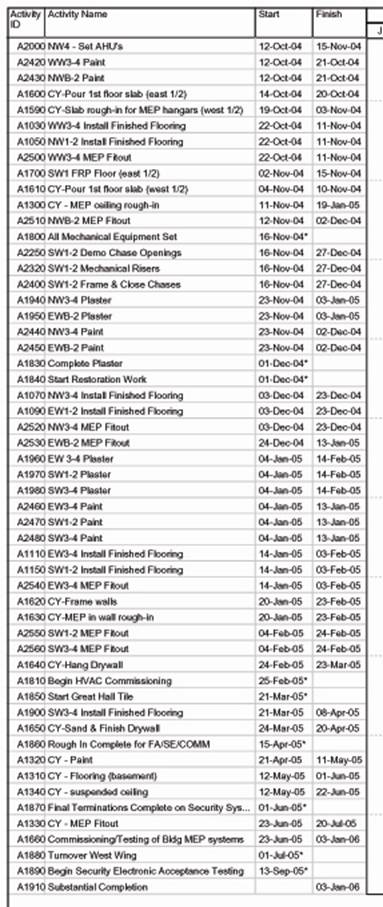

Narrative

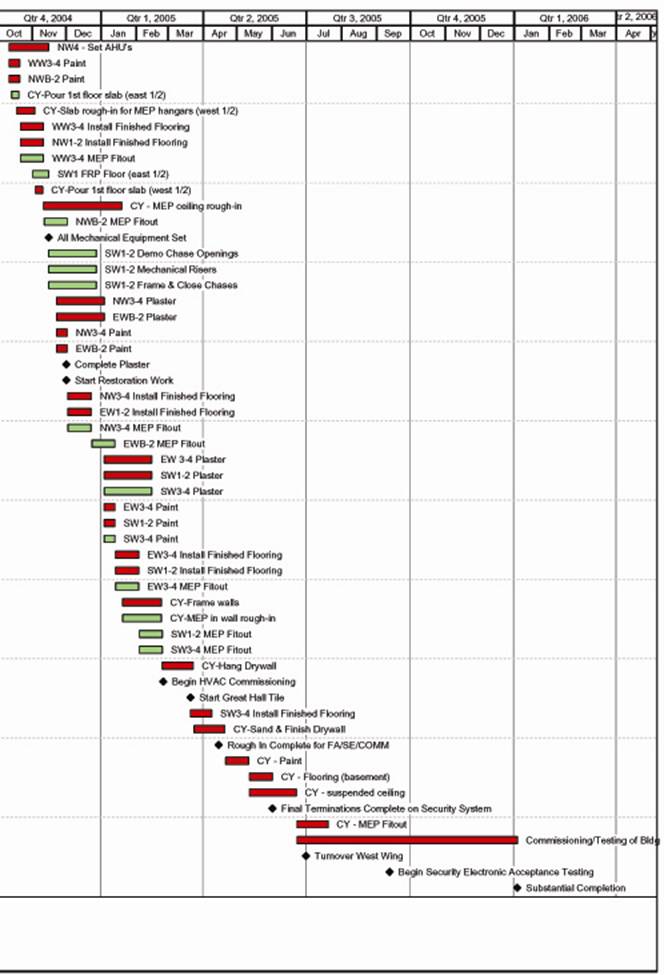

It

is pretty obvious, when looking at the CPM schedule below, the project had a

very long design period. The design

period includes the schematic design, design development, and the creation of

the construction documents. When the

documents were completed there was a separate contract to perform the original

demolition work as well as cleaning and repointing the façade of the

building. There was also a new roof, and

new windows put on the building. Once

the first contract was finished, the bid documents for the current project went

out, and the project was bid over a three year period.

Once the contract was awarded to

Hensel Phelps to renovate the building, the first steps were the mobilization,

then demolition and abatement of the building.

Due to the sheer size of the building, there is excessive overlap of

activities. Once areas have been abated

of all hazardous materials the work on the chases can begin. First structural supports are put in where

necessary to support upper floors while cutting the chase openings. Next the structural reinforcements are

installed in the chases to make up for the structural brick that was

removed. Then the mechanical and

plumbing systems run their risers through the chases. Once all of the mechanical work is in place

the chases can be framed. Occurring

concurrently is the demolition of the floor slabs to run the electrical conduit

within the floors. Once the conduit is

roughed in the floor can be poured using concrete.

Once all of the basic MEP work is roughed in the chases can be

closed, followed closely by drywall and plaster. When all of the necessary coats of plaster

are in place the painter can come through and paint the walls and

ceilings. When the painter is through

with certain space, the area can be fitted with lights, louvers, fixtures, etc. The flooring is then installed, whether it is

marble, tile, carpet, or wood. Once the

MEP fitout is well under way, the commissioning of the various systems can

begin. When an area has all of its

finishes, the museums can begin to move in and take them over. Lastly, there is some sitework that needs to

be accomplished as well as the demobilization of all of the trailers,

equipment, etc.

Demolition

·

Abatement

- There is abatement requirements for both asbestos and lead. The lead is existent in the current paint on

the walls. The paint has not been

removed ever since the original construction of the building, and has undergone

several renovations and remodeling efforts.

There was limited asbestos since the building was complete before asbestos

was popular and therefore was only used in a limited capacity during the last

major renovation in the 1950’s.

·

Demolition

– The major area of demolition for the project relates to the expansion of the

existing chimneys to make room for the pipe chases. Throughout the project there are over 500

chases that need to be located and opened, typically from floor to

ceiling. Then they need to be expanded,

often both wider and deeper, to accommodate the duct or pipe running vertically

through the space. There is also some

demolition required for through wall penetrations for the duct and pipe as

well. Also, there are an extensive

number of through floor penetrations for electrical conduit since it is run in

the floor in all of the gallery spaces.

Structural Steel Frame

·

There

is steel reinforcement, steel angles, needed for the existing granite slab

throughout the North and West wings of the third, third mezzanine, and fourth

floors.

·

In

the mechanical chases, often steel C channel is bolted into the masonry walls

for support if the chase is expanded from its original size.

·

In

the courtyard there is structural steel spanning the auditorium area. The connections are mostly bolted, though at

the beam splices there are full penetration welds as well.

·

The

erection of the steel requires a 500 ton mobile crane with an extension to

reach over the building into the courtyard.

The locations to set up the crane were limited due to the downtown

location. G Street between 7th

and 8th Streets needed to be closed for two weeks to erect the steel

in the courtyard.

Cast in Place Concrete

·

The

formwork for the concrete for the vertical placements was all built in place

from wood, or used the soldier beams and lagging that were in place for the

excavation.

·

The

formwork for the piers and pile caps consisted of some gang forms and wood

forms for some of the unique shapes required.

Mechanical System

·

The

mechanical system is split into two separate parts, one running up from the

basement through the second floor, the other starting at the top floor and

feeding down to the third floor.

·

The

mechanical rooms for the lower floors is are located in the basement of the

West wing. The mechanical and electrical

equipment take up almost the entire basement of the West wing.

·

The

mechanical rooms for the upper floors are in the North wing and the north half

of the West wing.

·

The

mechanical system is an all air system with vertical distribution using duct

through existing chimneys.

·

The

fire suppression system is an all water system.

Due to the historical nature of the building there are some spaces that

do not have sprinklers so as not to take away from the historical nature of the

space, such as the Lincoln Ballroom.

Electrical System

·

The

electrical system feeds the building with two 13.8 KVA lines coming into the

basement at two separate points.

·

The

building, besides having two separate feeds, has an UPS system with a diesel

generator to maintain power.

Workers

moving transformer into basement

Masonry

·

The

building is an existing load bearing masonry building. Near the foundation the walls are several

feet thick.

·

The

majority of the building is brick; however there are granite and marble

columns, and the façade is made up of sandstone, granite, and marble.

·

Where

there has been demolition the building is, as much as possible, to be built

back with brick and block. The use of

similar materials lowers the risk of structural issues related to uneven

expansion and contraction.

·

A

unique note for the masonry is when new brick is put into place; the brick used

must be uniquely different from the existing brick. The specifications require the unique brick

to ensure that in the future it is easier to identify which was original and

which was installed in the renovation for historical purposes. The contractor therefore used both blonde and

concrete bricks for the new construction.

·

Scaffolding

was required in the interior of the building when doing work on the

chases. The scaffolding was used for two

reasons:

·

To

support the existing structure when demolition undermined supports for the

floor above

·

When

doing work at some of the higher elevations.

Some of the grand spaces have ceiling heights approximately 40 feet

above the existing floor.

Support of Excavation

·

The

support system for the excavation of the courtyard consists of soldier beams

and lagging.

·

The

support system remained in place and served as the rear form for the cast in

place concrete walls in the courtyard.

·

Since

the excavation had portions of existing building along the west, north, and

east faces dewatering was only an issue due to rain. When necessary a pump was brought in to

dewater the courtyard.

Actual Cost

·

Total

Building Renovation Cost per Square Foot (per base bid): $261.78/SF

·

MEP

System Cost per Square Foot (Mechanical, Electrical, Plumbing, Fire

Protection): $94.24/SF

D4 Cost Estimate

·

What

is D4? - D4 is software for estimating projects based on historical project

costs. The program has a database of

projects and the database can be searched by a list of criteria to find

projects similar to the project being estimated. Once a list of similar projects is put

together, the user chooses the projects best most like their project and using

the software can “Smart Average” them.

The software weighs the different buildings to account for number of

floors, floor heights, etc. The outcome

is an estimate split up into the 16 CSI divisions. The user then has a base estimate to work

from and can make adjustments for the unique characteristics of their actual

project.

·

D4

Base Estimate

·

Adjusted

Estimate

|

CSI Division |

Area |

D4 Original Estimate |

Adjustment |

New Amount |

Reason for Adjustment |

|

1 |

General Requirements |

$5,298,710 |

$6,000,000 |

$11,298,710 |

4 trailers, Staff of

20+, 3 year job, trucks for supts,

money for parking |

|

2 |

Sitework |

$5,496,093 |

$5,000,000 |

$10,496,093 |

extensive lead &

asbestos abatement, demolition work, CY

work |

|

3 |

Concrete |

$10,924,196 |

$0 |

$10,924,196 |

repouring all of the

floors, CY foundations &

floor |

|

4 |

Masonry |

$2,109,917 |

$1,000,000 |

$3,109,917 |

all masonry bldg, lots

of repair work |

|

5 |

Metals |

$4,910,729 |

$0 |

$4,910,729 |

|

|

6 |

Woods & Plastics |

$1,030,431 |

$2,000,000 |

$3,030,431 |

repairing historical

wood, large amount of exposed wood |

|

7 |

Thermal & Moisture

Protection |

$1,754,023 |

$0 |

$1,754,023 |

|

|

8 |

Doors & Windows |

$1,942,231 |

$0 |

$1,942,231 |

|

|

9 |

Finishes |

$4,763,065 |

$3,000,000 |

$7,763,065 |

high end finishes,

hand made, materials from

overseas |

|

10 |

Specialties |

$3,573,145 |

$0 |

$3,573,145 |

|

|

11 |

Equipment |

$1,776,191 |

$0 |

$1,776,191 |

|

|

12 |

Furnishings |

$1,348,894 |

$1,000,000 |

$2,348,894 |

casework, auditorium

seating |

|

13 |

Special Construction |

$1,136,200 |

$2,000,000 |

$3,136,200 |

blast resistance,

measurement & control

instrumentation |

|

14 |

Conveying Systems |

$1,847,123 |

$2,000,000 |

$3,847,123 |

installing multiple

elevators |

|

15 |

Mechanical |

$7,791,697 |

$10,000,000 |

$17,791,697 |

two systems, extensive

ductwork, new sprinkler system |

|

16 |

Electrical |

$6,723,695 |

$10,000,000 |

$16,723,695 |

high end security

system, new data lines, UPS

system |

|

|

Totals |

$62,426,340 |

$42,000,000 |

$104,426,340 |

|

RS Means SF Cost Estimate

Dimensions: Courtyard

- the new construction portion of

the building.

Assumptions:

·

1 Story Building

·

24’ Story Height

·

Precast Concrete w/ Steel Frame

Revisions to Standard

Data:

·

Interpolation between 24,000 SF and

27000 SF to get numbers

{Formula = 24,000 +

(25,000-24,000)/(27,000-24,000)}

·

Modification from 640 LF of Perimeter

to 700 LF of perimeter (4.70 / 100LF)

$2.82/SF

= (60 LF * 4.70 / 100)

·

Change to Padded Seats costs $207 EA

for 300 seats

$207 * 300 = $62,100

RS Means Estimate:

|

$111.81 / SF + $2.82 / SF |

|

|

|

|

|

|

|

$114.63 / SF |

X 25,000 SF = |

$2,865,750 + |

$62,100 = |

$2,927,850 |

|

|

Comparison of Estimates to Actual Costs

·

D4:

The D4 Estimate

was considerably lower than expected.

The projects used to “Smart-Average” in order to come up with an

estimated project cost were not very similar to the Smithsonian Institution

Patent Office Building. The projects

used ranged from an arts center, to the National Archive II bldg. The trouble lies in the unique nature of the

Patent Office Building. Estimating for a

renovation project varies significantly from building to building because of

each building’s distinctive history.

·

RS

Means:

The RS Means

estimate appears to below what the courtyard should probably cost. The Smithsonian Institution is sparing no

expense for their project, and the high end finishes they are using is not

apparent in the SF cost of the courtyard.

The SF cost is less than half of what the SF cost for the entire

building is for the base contract. Since

the courtyard is basically a new project within the renovation, the cost per SF

should probably be a little less than the rest of the building, since there is

limited demolition and no abatement. The

estimate also cannot show the lack of access to the courtyard that will raise

costs of doing any work requiring equipment in the area.

Site Plan of

Existing Conditions

·

Site

Plan featuring temporary facilities, property and boundary lines, existing

and new utility lines, traffic flow, and adjacent buildings. (Site plan is not currently complete but will

be soon)

Preferred

Methods of Construction

·

Washington,

DC is well known for its concrete construction due to the height limitations on

buildings within the city and the ability to have smaller space between floors

with a cast in place concrete building rather than a steel structure.

·

Since

the site is downtown, there is limited space within the construction

boundaries. Nonessential uses of space

are, when possible, moved off-site. For

example, parking is off-site at local parking decks and other available

locations.

Recycling/Dumping

·

Recycling

is being done for the office paper used on site.

·

There

are several materials in the building that are being restored and reused. There are existing tile and marble floors

that have been taken up to be cleaned and put back in place.

·

Tipping

fees in the Washington area run $350 to get a 30 yd dumpster pulled and dumped.

Soil/Subsurface Water Conditions

·

The

soil found when excavating in the courtyard …

·

Since

the courtyard is within the building footprint, there were minimal problems

with onsite water. The only time it was

an issue was due to inclement weather.

Smithsonian Institution

·

“The

Smithsonian, as an independent trust instrumentality of the United States,

conducts scientific and scholarly research, administers the national

collections and performs educational public service functions, supported by its

trust endowments and revenues, gifts, grants, contracts and funds appropriated

by the Congress.” (Taken directly from http://newsdesk.si.edu/)

· The Patent Office Building is going to house three distinct art museums: The National Portrait Gallery, The Smithsonian American Art Museum, and The American Art Archives. The building is being renovated because of a number of issues related to the age of the building. When a building reaches a certain age the mechanical, electrical and plumbing systems become outdated. There is significant wasted energy, and there are a number of hazards related to the asbestos and lead in the building.

·

The

total cost of the building, including previous work to clean the façade, fix

the roof, and replace the windows, combined with design and development costs

and some planned future work, will be approximately $210 Million.

·

The

quality expected in the building is extremely high. The level of finishes required in the

interior spaces are the highest possible on their respective scales. Many items are hand made, or made to resemble

the buildings original makeup, as well as restoration of existing materials

that have undergone 170 years of wear.

The evidence of the strong interest is very clear in the specifications

for the building through the quality control measures and the very specific

nature of the specifications for finish materials. Also, the project is an historical building

as well as an art museum, both of which are of an extremely public, visible

nature and the visitors coming into the building will have high expectations,

therefore the owners want to meet the expectations coming in. Also, there is a whole section of the

specification related to the historic nature of the building.

·

The

schedule is designed to have the building substantially complete and open to

visitors on July 4th of 2006, 170 years after its original

construction on a significant American holiday.

The schedule includes some phased occupancy to allow the museums to all

have some space within the building before the grand opening, as well as

working out the commissioning of the systems and the move-in of the significant

amount of art to be displayed.

·

The

safety is of utmost importance due to the hazardous contents and the age of the

building creating the potential for very dangerous situations. The owners’ emphasis on safety can be clearly

seen through their hiring of a general contractor with a track record for

safety, and their requirement of a full-time safety manager on site throughout

the entire project.

·

There

is, as mentioned above, phased occupancy for the building. The entire West wing of the building is

turned over to the owner more than a year in advance of the substantial

completion of the project.

·

The

keys to completing the project to the owner’s satisfaction lay in:

·

Completing

the project in a timely manner, due to the significance of the grand opening

date.

·

Providing

a project up to the quality expectations of the representatives of the multiple

museums who will be occupying the space.

·

Completing

the project within a reasonable range of the budget.

·

Having

no major injury throughout the construction.

The second technical assignment concentrates

more on some of the key features of the construction. There is a more detailed schedule, shifting

from 30 to 200 items. There is an

assemblies estimate of a particular portion of the building. There is a summary and analysis of the

contracts employed on the project. The

assignment asks for a breakdown of the way the project staff is allocated. The assignment also includes the process of

coordination that was followed as well as the areas where issues occurred. The last item is a summary of the meetings

attended at the PACE Roundtable Seminar.

Analysis

of Key Construction Features Wednesday October

27, 2004

·

Detailed

Project Schedule pdf

·

Critical

Industry Issues pdf

Summary

Memo 10/27/04

The following report is a a more in depth analysis of certain

features of the construction that set this project apart. The analysis covers a more detailed project

schedule broken down by wing and by activity.

There is an assemblies estimate of the structural system in the

courtyard. There is an overview of the

contractual relationships on the projects and their appropriateness. There is a staffing plan for the general

contractor showing the way the project is broken up and managed. The design coordination section covers the

plan for coordinating the installation of the MEP systems in the building and

some of the areas of conflict. Included

is a write up of certain sessions from the PACE roundtable meeting held at the

Penn Stater Hotel & Conference Center on October 7th. Last is a brief overview of the soils report

that was not available for the first technical assignment.

Included in this

submission are a detailed project schedule, an assemblies estimate of the buildings courtyard structural

systems, an overview and evaluation of the contracts used on the project, the

staffing plan for the general contractor, an overview of the plan for the MEP

coordination, a write-up of the PACE roundtable event and an overview of the

existing soils conditions on site. The

highlights of the submission are the dual systems employed in the courtyard

structural system and the differing costs.

The contracts employed on the project are rather straight forward with

lump sum contracts being used in all instances.

The highlight of the contracts was the use of a best value selection

process for the general contractor. The

staffing plan is of a typical nature for how Hensel Phelps usually staffs a

job, though due to the size of the job there is a large staff on site. The age and historic nature of the building

introduce a number of interesting aspects into the design coordination for the

MEP systems. The key area of trouble in

the field tends to come from the conversion of the old chimneys into mechanical

chases. The critical industry issues

write up covers the Performance Contracting, Green and High Performance

Buildings, and the Leadership Jump Start sessions. The direction the roundtable has pushed my

research interests has been towards LEED rating and green building

systems.

|

|

||||

|

|

|

||||

|

|

The assemblies

estimate looks at the structural systems in the Courtyard of the Patent Office

building. The courtyard’s structural

elements were chosen because the courtyard has two different structural systems

being used. The west half of the

courtyard is structural steel with a one way slab. The east half is a structural two way slab

with concrete cast in place columns.

Around the perimeter of the courtyard is a structural concrete wall with

varying height (the auditorium section in the west half slopes downward and has

higher floor to ceiling height. The

courtyard will also be looked at in detail in the third technical assignment

with a detailed estimate.

Material Takeoff

Material

Takeoff Data

Data

Data

|

Item |

Dimension |

Quantity |

|

CIP Columns |

14' Tall,

15" square |

35 |

|

Steel Columns |

18' Tall, 48

plf |

24 |

|

Steel Columns |

18' Tall, 58

plf |

5 |

|

One Way Slab |

30' x 6' |

1 |

|

|

200' x 7' |

1 |

|

|

20' x 40' |

1 |

|

|

53' x 16 |

1 |

|

Totall |

|

3250

SF |

|

Two Way Slab |

80' x 43' |

1 |

|

|

53' x 3' |

1 |

|

|

33' x 6' |

1 |

|

Totall |

|

3800

SF |

|

Slab on Grade |

|

7050

SF |

|

W shape Beams &

Girders |

3250 SF |

1 |

|

CIP Walls |

18' x 53' |

2 |

|

|

18' x 16' |

1 |

|

|

14' x 75' |

2 |

|

|

14' x 53' |

1 |

|

Total |

|

5000

SF |

RS Means Costwork Estimate

|

Source |

Line Number |

Description |

Quantity |

Unit |

Ext. Material Incl O&P |

Ext. Installation Incl O&P |

Ext. Total Incl O&P |

Zip Code Prefix |

Type |

Release |

|

Assembly |

A10301202280* |

Slab on grade, 4"

thick, light industrial, reinforced |

7,050.00 |

S.F. |

$13,481.43 |

$16,020.35 |

$29,501.78 |

20004 |

Union |

2003 |

|

Assembly |

B10102030900* |

CIP col, sq tied,200

K,14' sty ht,14" col,196 PLF wt,4000 PSI conc |

35.00 |

V.L.F. |

$407.73 |

$1,679.63 |

$2,087.36 |

20004 |

Union |

2003 |

|

Assembly |

B10102083800* |

Steel columns,125 KIPS,20'

unsupported height,48 PLF weight,8" wf |

24.00 |

V.L.F. |

$851.76 |

$149.93 |

$1,001.69 |

20004 |

Union |

2003 |

|

Assembly |

B10102085000* |

Steel col,200 KIPS,20'

unsupported height,58 PLF weight,12" wf |

5.00 |

V.L.F. |

$215.08 |

$31.23 |

$246.31 |

20004 |

Union |

2003 |

|

Assembly |

B10102173800* |

CIP slbs, 1 way,sgl 15'

span,200 PSF supimp,8.5" thk,306 PSF tot |

3,250.00 |

S.F. |

$13,394.06 |

$23,719.41 |

$37,113.47 |

20004 |

Union |

2003 |

|

Assembly |

B10102206600* |

CIP bm&slb,2 way,25x30',200PSF

supimp,20"col min,8.5" slb,341PSF tot |

3,800.00 |

S.F. |

$22,801.90 |

$40,275.82 |

$63,077.72 |

20004 |

Union |

2003 |

|

Assembly |

B10102418980* |

Wf b&g,35x30'

(BXg),200 PSF supimp,36" d,.874 SF/SF fprf,281 PSF tot |

3,250.00 |

S.F. |

$39,502.13 |

$16,420.98 |

$55,923.11 |

20004 |

Union |

2003 |

|

Assembly |

B20101017400* |

Conc wall reinforced, 8'

high, 12" thick, plain finish, 3000 PSI |

5,000.00 |

S.F. |

$25,254.00 |

$71,765.85 |

$97,019.85 |

20004 |

Union |

2003 |

|

|

|

|

|

|

$115,908.09 |

$170,063.20 |

$285,971.29 |

|

|

|

*Note:

The table above was put together using RS Means Costwork 2004 Program

which allows the inupt of the zip code of the project for location cost

calculations as well as the year of the project start to convert for time value

of money.

When reviewing the data it is interesting to

not the steel system employed on the west half and the concrete system on the

east half show a significant difference in price. The column systems are comparable, but when

looking at the slabs employed on both, the one way slab used on the west half

cost about half again as mush as the two way slab on the east half when the

cost of the steel beams and girders are taken into account. There seems to be a prime opportunity here to

find an alternative system that would make the courtyard one consistent

structural system (making construction simpler) and at the same time making the

system itself less expensive from a materials standpoint.

Hensel

Phelps - GC

·

The main contract for the construction of the

building was a lump sum contract given to the GC on a best value decision

process

·

Hensel Phelps bid was, in fact, the highest

of the bids put in

·

The reasoning behind the Best Value selection

was mainly due to the historic nature of the project and the emphasis on

preservation of the building and its unique materials

·

The owner felt that using a lowest bidder

selection process would result in a lower quality final product from the

desired results

·

The project has no OCIP or CCIP requirements,

there are insurance requirements, but they are of a standard nature for

construction projects and in line with Hensel Phelp’s normal insurance

requirements, (eg. General Liability, Workers Compensation, etc.)

·

The bonding on the project is a little

unusual, the GC has a performance bond for 100% of the contract value, however

the payment bond is only for 50% of the value of the base contract

·

The contract contains no incentives, rewards,

shared savings clauses, nor liquidated damages clause

Subcontractors

·

The contracts between Hensel Phelps and its

subcontractors is a standard lump sum contract used for all of its subs

·

The insurance and bonding requirements from the

owner are passed on in the same format to all of the subcontractors

·

The contracts follow the same lump sum format

as the main contract between Hensel Phelps and Smithsonian for simplicity of

management, changing to a different style of contract could lead to a variety

of complications

Hartman-Cox

Associates

·

The contract with the architect was

originally on an hourly basis, with the architect submitting a log of the hours

spent by themselves as well as the consulting engineering firms

·

The contract was amended later to change to a

lump sum contract due to the excessive tracking work needed by both the

architect and the owner in order to maintain proper billing procedures

Bovis

Lend-Lease

·

The contract with the Construction Management

Agency is assumed to be a Lump Sum contract, which would fall in line with the

rest of the contract types

·

The CM is focused on managing the

construction process so the insurance requirements would match those of the

contractors and subcontractors, with the exception of liability relating to the

work in place

·

It is possible that the CM may have Errors

and Omissions Insurance due to their

involvement in constructability reviews and the potential for liability

in that area

Appropriateness

of Contracts

Hensel

Phelps

·

The lump sum contract, chosen with the Best

Value selection method, seems quite appropriate due to the focus of the owner’s

interests on the quality of the final

product

·

Using the Best Value process allows the owner

to weight other aspects of the bidding organizations including the experience

of the project team and the thoroughness of the construction plan, budget,

schedule, etc.

·

Smithsonian Institution has worked with

Hensel Phelps on other projects in the past, namely the new National Air and

Space Museum at Dulles Airport, which may have influenced Smithsonian’s

decision to use Hensel Phelps

Subcontractors

·

Due to the size of the project and the

complexity, the use of a boilerplate contract simplifies the process to simple

modifications from a universal base contract

·

There are obviously some modifications based

on scope of work and preferences of subcontractors on certain terms and

clauses, however the contracts are very consistent

·

Using a boilerplate contract for all of the

subcontractors seems very appropriate considering the number of subs employed on the

project and the long duration

·

The contract type also is appropriate because

of its alignment with the main contract between Smithsonian and Hensel Phelps

Hartmann-Cox

Associates

·

The use of an hourly contract for the design

firms seemed very inappropriate

·

The fact that the contract did not match the

project was born out when the contract changed to a lump sum partway through

·

The use of the lump sum seems appropriate,

again, because of its alignment with the contracts for the rest of the project

and the amount of work it saves for both the designer and the owner

Bovis

Lend-Lease

·

Using a lump sum contract is the right choice

for the construction management firm for much the same reason as for the

general contractor, the level of quality requires a knowledgeable and

experienced builder

The

alignment of all of the contract types saves the owner a considerable amount of

work because the system they use to track all of the companies in their employ

is all the same format and they are getting billed in the same manner by all

parties. The owner is experienced in

construction and was pretty wise in their decision for the proper delivery

method for the project and the selection process they used in choosing a

contractor.

|

|

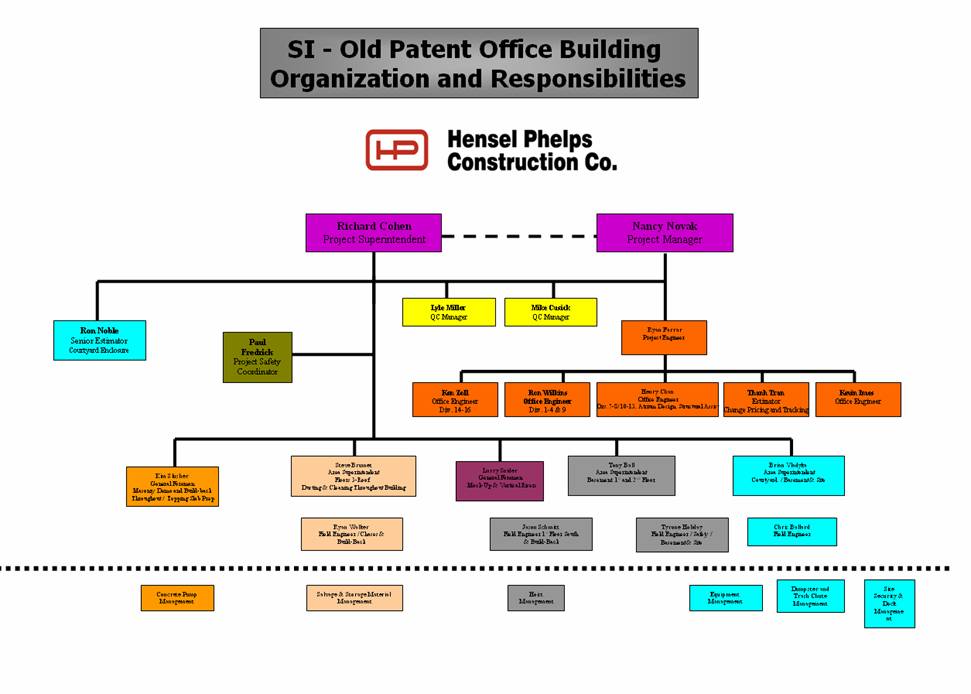

Staffing Plan

·

The staffing plan for Hensel Phelps is fairly

standard following the set up they typically use on a project

·

The main division is between the field staff

and the office staff

·

The Project Manager heads the office team

·

The Project Manager is in charge of all of

the project documentation and overseeing of the contractual relationships on

the job

·

The Project Engineer is directly under the

project manager

·

The Project Engineer performs the accounting

and key documentation for the project

·

The Project Engineer also serves as the main

conduit of information flow between the owner, architect, Construction Manager,

and the Office Engineers

·

The Office Engineers function under the

Project Engineer and are divided up among specification sections and their

respective subcontractors

·

The Office Engineers are responsible for the

submittals, RFI’s and necessary procedures related to their spec sections and

the respective documentation

·

There is also an Office Engineer assigned to

tracking the change orders and potential change orders due to the vast number

of changes on a project of this size

·

The Project Superintendent is the respective

head of the team that runs and performs the

actual construction of the building

·

The Project Super focuses on getting the

project built and maintaining the quality, schedule, and safety aspects of the

job

·

The Project Super also runs the construction

of the mock-up to work with subcontractors performing their work for the first

time and to ensure the result meets the expectations of the designers and the

owner

·

Directly under the Project Superintendent are

several Area Superintendents and General Foreman who are responsible for

specific sections or aspects of the building

·

The Area Supers are divided up with one

taking the sitework and courtyard construction, one taking the lower half of

the existing building, and one taking the upper half of the building

·

The General Foreman are split into the Masonry

Foreman due to the extensive masonry work throughout the building, and a

Foreman in charge of the chases/vertical risers for the mechanical work

·

The Area Supers and the General Foremen are

all designated certain managerial aspects for the project, such as equipment

management, material storage, etc.

·

Under the Area superintendents are the Field

Engineers

·

The Field Engineers are responsible for the

layout of work for the respective areas of the Supers

·

The connection between the field and the

office teams lies in the Quality Control department with a manager in the

office to focus on documentation and a field inspector to review work and

ensure proper installation

Overall

The staffing set up for

the project works well. Hensel Phelps is

a large firm and has been using the same general staffing plan for a number of

projects over many years. The main

complication for this project lies in the size of the project and the

coordination of the large staff it requires.

There are communication problems, though daily meetings between the

field staff and the office staff clear up most difficulties and help focus the

work for that day. The project is manned

at approximately the right number of personnel.

Most staff members work approximately a 50 hour week. Adding one or two people to the project would

lighten the individual load of a few people, but would add to the coordination

needed for the whole project and in the end most of the staff’s load would not change

significantly. The integration between

the field and the office is fairly strong.

Hensel Phelps has a fairly regimented program for personnel coming up

through the ranks and upper level personnel are familiar with the duties of the

other staff and know who’s responsible for which tasks. They are also there to assist in making sure

the newer staff can do the work expected of them. There is a strong atmosphere of guidance

without overbearing control. The

staffing plan is also distributed to the subcontractors, Construction Manager,

the Design team, and the owner. Sharing

the staffing plan with the project team allows for the communication to go more

smoothly between the different entities on site. The owner and all of the subcontractors still

have a main point of contact, but they are also aware of the duties of the

entire team and it is easier for them to know whom to consult in various

situations and

conflicts.

Scope / Contract Requirements

Coordination of MEP work is required by contract

for the Mechanical/Plumbing,

Electrical, and Fire Protection Contractors. The contracts call for the overlaying of

respective shop drawings to identify areas of conflict and the resolution of

those conflicts. The first step required

is for a schedule of the order of coordination drawings listing the areas of

main

concern and the dates when the coordinated drawings will be submitted to

the designers. The mechanical

contractor, Pierce Associates, will take the lead in coordinating the drawings.

Intensity

Since the building is an

art museum, the mechanical coordination does not appear at first glance to be

an intensive one. The age of the

building and the unique structure make the building rare by nature, the systems

used in it have to function accordingly and therefore tend to be somewhat

complex so they do not impact the nature or use of the building. The mechanical areas will require a fair

amount of coordination due to the amount of equipment needed to supply a

building with such immense size.

The use of an all air

system increases the amount of space the mechanical system will take up. Duct work is one of the most space consuming

systems in a building. The building’s

layout by wing causes the systems to have long runs of duct, pipe, and conduit

in order to feed the various spaces in the building. On top of the layout, the system is split

into two parts, one feeding up from the basement and the other feeding down

from the fourth floor. Having two

mechanical rooms means having to coordinate two separate mechanical rooms.

One of the details of the

building that simplifies the coordination process is the lack of ceilings in

the various spaces. There are very few

spaces in the building that have a ceiling besides the structure of the floor

above. The mechanical rooms and the

basement spaces have exposed MEP work running openly. The electrical conduit is run in the floor

slabs. Most of the duct that feeds the

spaces is run in vertical chases that do not have horizontal runs on the floor

but feed the space from the sides.

One of the unique areas

that requires coordination is the cooling tower. The cooling tower requires a new steel

structure to be erected on top of the roof.

The cooling tower will require coordination between the steel and the

mechanical lines that feed the cooling tower.

Deadlines

The shop drawings, after

the plans have been coordinated, must be submitted to the respective engineers

for approval of any changes that needed to be made. The schedule of submissions for the drawings

was drawn up in advance based on the construction schedule of when those areas

would be built.

Problems, C/O’s & Field

Conflicts

The key problems

associated with the MEP systems focus on the use of the former chimneys as the

riser space for the mechanical chases.

The chases are typically 1 ft by 1 ft when they are first opened

up. The chases need to hold the

ductwork, as well as some other plumbing and mechanical risers. In almost every case the chases need to be

widened in order to fit the MEP work in place.

Widening the chases creates a number of structural issues due to the age

of the building and the fact it’s structural masonry. There are questions about the structural

stability of all of the extra holes and openings being made. Also, the reinforcement to support the

structure is typically steel channel which expands and contracts differently

from masonry and could lead to cracking and other structural issues.

The age of the building

also means that there are not a good set of As-Built drawings to work from when

the systems were designed. Many problems

arise when opening the chimneys to see the existing size. Often the structural engineer has to come to

site because a chases do not conform to the typical structural details for

reinforcing shown in the drawings.

Once installation of the

MEP rough in and equipment began, weekly coordination meetings started. The meetings look at the 4-week look ahead

schedule to find areas the subcontractors will be working that may have conflicts. The conflicts are worked out in advance to

minimize schedule impacts

One of the solutions for

coordination in the West Basement, the main mechanical and electrical space,

was the use of metal racks to support some of the MEP runs. The

racks hold up the lowest layer of ductwork and piping. The system enables the contractors to have

two tiers of MEP systems running down the corridor in the basement. The system also detracts from the amount of

structural support needed from the arched masonry ceiling above.

One of the major changes

that occurred with relation to MEP coordination was in the East Basement. Originally the MEP systems were to run

exposed from the ceiling as in the West Basement. The space is going to be used for certain

offices and the occupants did not want exposed systems running through the

corridor (the ceiling height was low to start).

The systems were changed so the mechanical and electrical systems run in the slab, requiring

the excavation of trenches due to the amount of conduit and ductwork going down

the corridor. The change required an

extensive amount of coordination to locate where the crossover of systems was

underground and also to work around the foundation as much as possible rather

than coring through the footings.

In the area where there is a ceiling (North

West of the 3rd floor) there

is a conflict of the mechanical equipment due to limited space above the

ceiling, resulting in the lowering of the ceiling. In the Luce Center, one of the “Great Spaces,”

there are display cases which require electric hook ups, the conduit needs to

be run under the floor for appearances sake and the floor is existing slate and

not easily fixed in case of a mistake or change.

In the courtyard the MEP systems have been

re-coordinated several times because of multiple changes from the owner, there

are extensive Mechanical and Electrical systems running above the ceiling in

order to support the auditorium. The

re-coordination effort is a strain on the personnel because they have already

performed the work and are in the process of planning the construction only to

have the whole area changed and they have to start again,

almost from scratch.

Session

1: Performance Contracting I: Rewards & Incentives

During

the first session, it was interesting to learn the contractors’ views on the

idea of rewards and incentives in contracts.

All of the contractors tended to be agree that some sort of reward or

incentive was usually a good thing in a contract. There was unanimous approval for shared

savings clauses.

There

was general agreement that performance based fees worked, though they felt

there should be some more objective criteria for assessing the

performance. They referred to the more

subjective areas as “working for tips.”

The other issue raised about performance based fees was the potential

for personality clashes between the contractor and the owner that could lead to

unfair assessments for the contractor.

When

the idea of incentives came up there developed some interesting conversation

about the manner in which owners went about dispensing the incentive. One example where an employer wanted to hand

checks directly to the GC’s employees was considered a serious issue. The manager felt the payment could lead to a

“mutiny” from other employees on other jobs who were not being compensated in

an equivalent manner when they were working to the same level. Also, the potential for new employees could come

to expect the incentives as money they were entitled to on every job. Also, because the employees were new they

might not perform in the owner’s best interests but try to get the most money

out of the owner, in effect working in their own best interest.

Other

incentives that were discussed were early completion incentives, safety awards

and the potential for more work from the owner.

One of the questions raised during the discussion was whether or not

early completion bonuses led to an overall lower cost for the project for the

owner due to the shorter period on site, or if the contractors were building in

extra money into their bid to cover the cost of earlier completion.

After

the discussion of fees the discussion moved to try to define what high

performance contracting actually meant.

The industry members present tended to agree that it went beyond being

on time and on budget for the project.

They felt serving the customer’s needs, beyond the requirements of the

contract, was where the step above came from.

The

key to being a high performance contractor, from the point of view of the

companies present, was in the people working for the company. The personnel needed to be able to adapt to

changing conditions, have continuity in education, and that success for the

project needed to be defined up front.

When the project was of significant length, the success might need to be

redefined multiple times. The question

was raised by the students about the relationship between contract incentives

and repeat clientele. The industry members

said that most of their work where they had incentives was with customers who

were repeat clients.

The

last topic discussed was the idea of a performance specification. The industry members said that if the spec

was a “true” performance specification then it would work, however most

performance specs were “hybrid” specs where some items were specified by name

and took away the performance potential for some of the systems. Also, there tended to be problems where there

were too many customers to please, such as at the Pentagon, where so many

people had a preconceived notion of what they were getting. Also, the key seemed to lie in the submittal

process to ensure the products submitted met the intent of the specification,

and the owner needed to be involved to see exactly what they were getting.

Another

question raised by industry members was why do incentives not always work

in contracts, certain contractors seem

to not work toward getting the incentives.

Session

2: Emerging Markets II: Green and

In

the second session the topic started with why do people pursue green

buildings. The main responses seemed to

be driven by the bottom line, whether that was governmental incentives, higher

turnover of merchandise, improved marketing, or possible fundraising

opportunities. The questions that were

raised were what are the legal aspects of a contractor pursuing the LEED

certification for a building, and one of the subs drops the ball, taking the

certification down a level. Who is now

the responsible party if the building does not reach the level specified? Is it the responsibility of the GC when a sub

came up short? What are the damages to

the owner?

The conversation then turned to a

delineation of what exactly we were talking about. The comment was raised that we were of course

talking about LEED, since it’s possible to be green without getting a LEED

certification. Another comment was

thrown out that LEED is basically equivalent to Energy Star on electrical

appliances, etc. If someone wants a TV

that uses low energy then they buy one with an energy star symbol, if they want

a building like that, they expect a LEED certificate.

The perspective then moved to that

of the companies. What are the actual

costs of gaining points at each certificate level. How do the costs change by region. Also, the business case needs to be proven

for companies to really be on board.

Someone brought up the point that when people built houses, etc., a long

time ago they were designed to be comfortable.

When air conditioning was developed we stopped designing that way and

just loaded up on the AC. Now we’re just

reverting back to what made sense in the first place.

The suggestion was made to come up

with a checklist of reasons to obtain each point with the incremental cost

changes associated with each point. For

example, if someone were looking at the point for the bike rack. The checklist would show the value/intent of

the point, a few reasons why someone might choose it, state the up front cost

of buying the appropriate number of bicycle racks and showers if necessary, and

the life cycle cost increase or decrease for the point. There would need to be a significant amount

of study to show the cost per SF to get each point since they are somewhat

interdependent. It might be possible to

generalize it to what is the minimum cost per SF to step from the bare minimum

of one certification to the next. There

would be less adjustment and the dependence of the points would balance

themselves out.

Another area that could be

researched would be which points are most and which are least often obtained on

a project. Then also correlate them to

what level of certification the building received. One area of suggestion, when comparing the US

to Europe, was cradle to the grave analysis of energy input into various items

involved in construction, as well as LEED point items. One question raised was how many owners get a

LEED certification, then decide not to pursue the certification on another project. What reasons do they have for this, is it the

cost of documentation, or are the projects no longer green, etc.

When recycling moved into the

forefront of the discussion, the issue was raised of how could the logistics of

recycling be handled. The area of

concern seemed to lie in the enforcement of the recycling plan. It was suggested that recycling could be

improved significantly through education of the workers, in the same manner

that safety has. Also, planning to

minimize waste on site can save a significant amount of non-recycled

garbage.

Guest

Speaker: Chris Hewitt of AISC: “Managing steel prices and a volatile

market.”

Chris

gave a brief overview of the myriad of issues that were causing the price of

steel to rise. He started by showing how

originally the price of steel was actually artificially low in the US due to an

oversupply, a strong dollar, and cost pricing of the milling and

fabrication. Recently, China has been

beginning to build up its infrastructure, and with the size of China the

affects of their purchasing has had a significant financial impact

worldwide. On top of that the American

dollar value has dropped, shipping prices are rising, and global demand has

increased. All in all the price of steel

has just been moved much closer to the global price of steel. The effect of China’s influence is not

limited to the steel market, the effect will also be felt in wood and cement as

well.

He then reviewed the five V’s that

have an influence on the steel prices.

Volume of work is actually less than what the American steel fabricators

can handle currently. The businesses can

handle about half again as much work as they are currently performing

(throughout the country, that does not mean that individual companies can

handle that much more work). Velocity,

the standard mill and fabrication cycle has not changed recently by any

significant amount. Value, mill prices

have risen by approximately 50%, raising project costs directly by 1.5-2%. Variety, many contractors are stockpiling

rebar in stock sizes to keep their prices artificially low for the time

being. With steel, stockpiling is not

easy due to the large variety of sizes specified in drawings. Volatility, the price of steel has been

unpredictable for the last 9 months, which has led to higher prices mainly to

protect those giving prices. All of the

issues together are leading to an increase of 10-12% for projects overall,

regardless of the materials used.

Some of the ways contractors can

manage the process is to bring the specialty contractors in early to get their

perspective and influence in minimizing the cost to the project. Some of the other ways to manage the costs

are through the management of expectations, through realistic risk

identification and acceptance, consistency completeness & coordination of

structural drawings.

Session

3: Leadership Jump-Start for Entry

Level/Undergraduates

The last session of the day focused

on Leadership, the characteristics needed for leaders, and the ways new hires

can learn to become good leaders. The

discussion started out in simple terms, set expectations, learn to be a good

follower as a starting point to being a good leader. One of the keys was in observing traits of

good leaders and people that others want to work for. Too often students rely on their technical

skills, they need to learn to delegate and give proper guidance when

delegating. Also, the delegation of

responsibility and authority need to go along with the onus of the task.

The students felt that they could

benefit from more feedback from companies.

The industry members replied that the students needed to learn to read

the feedback they were already getting.

Possibly a class on reading body language would be beneficial. The idea that motivation and initiative were

the most commonly sought traits arose.

Also, the idea that the company’s goals, mission, values, vision, etc.,

should be thoroughly driven into the new company members. Also, new hires should be given an

understanding of the potential growth path that is available to them and that

through their understanding they can define their own path through the

company.

The value of appropriate mentors was

touted as a strong method for weaving new staff into a company. The comment that if you don’t make a mistake

then you’re not trying hard enough. The

new hires should make mistakes, but also should own up to them immediately so

they have an opportunity to learn and grow.

Also, the reasons for making the mistakes should be worked through so

the errors are legitimate and educational, not through laziness or

ignorance. A potential research question is what first

and second year hires in a company find to be their most valuable resources and

what resources they wish they had available, as well as what they wished they

new about companies before they went to work for them.

The areas that industry members said

they were expecting from new staff was commitment and flexibility, the challenge

and reward aspects of the construction industry as an incentive, people have to

be ready to respond and make decisions because those are what’s needed in

construction. Also, new members of the

staff should be ready to challenge the company to make them work, learn to be

good at face to face conversation. The

issue of

reading body

language was reiterated. Lastly, the

effective use of email since the “now” generation has a tendency to avoid

confrontation.

- The soils found on

site were consistent with the prevailing soils in the area, mainly Silty

Sand, Clayey Sand, and Lean clay

- Some construction

debris and brick fragments were found in the samples

- The water table

was not encountered in any of the boring samples, nor evident in the holes

within 24 hours after the samples were taken

- Based on the

location of some of the clays found, there is potential for water

appearing and dewatering will most

likely be needed

General Site Preparation Suggestions

·

The existing clay and clayey soils should be

removed from the site

·

The remaining sand should be stockpiled for

reuse as backfill

Foundation Recommendations

·

The soil is quite capable of supporting a

standard spread footing, but some of the underlying clay layers will most

likely lead to some differential settlement

·

A deep foundation system is suggested to

remove the effects of the underlying clay soils

·

Pressure injected concrete piles are

suggested

·

Driven piles are not suggested due to the

impact it may have on the existing structure

Excavation

·

The suggested shoring method for excavation

support is sheeting and shoring

·

The depth of excavation ranges from 20 to 25

feet

·

The max effective stress value of 25 degrees

and max cohesion of 150 psf is recommended for preliminary design of the sheeting

and shoring system

Chemical Analysis

·

A geoprobe of the soils on site were taken to

assess the presence of hazardous compounds within the soil

·

The test found the presence of arsenic,

chromium, copper, lead, nickel, and zinc

·

The levels of contaminants found were low

enough that the soil was classified as non-hazardous for disposal purposes

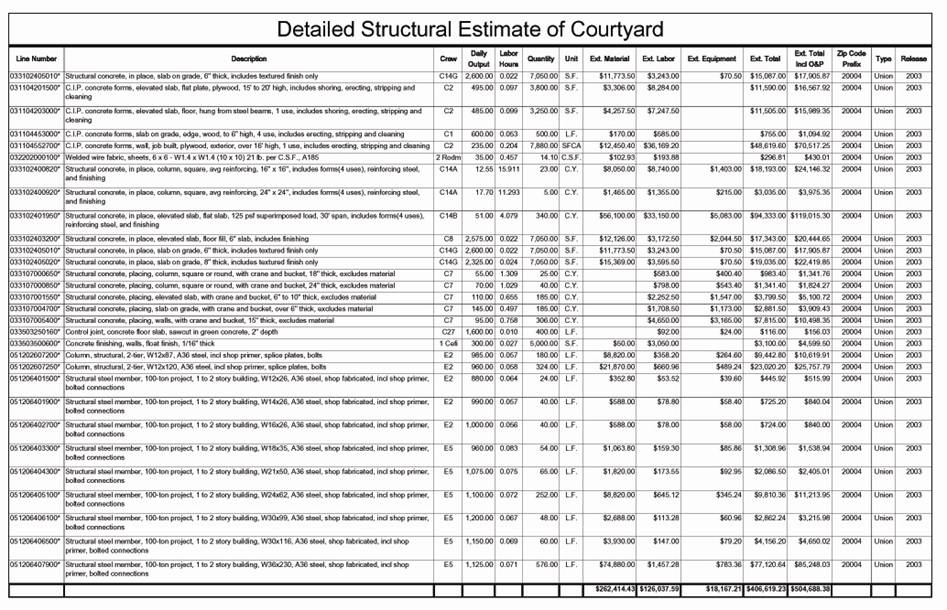

The final technical assignment turns

more towards a more focused look at certain aspects of construction. There is a more detailed breakdown of the

site with different layouts for the various phases. A summary of the temporary utilities employed

on the project, as required by the specification. There is a detailed estimate requirement of a

specific system in the building, in particular a system that will most likely

be analyzed later on in the thesis.

There is a requirement for an in depth general conditions estimate. The last portion is the proposed methods to

be used in the research analysis in the Spring.

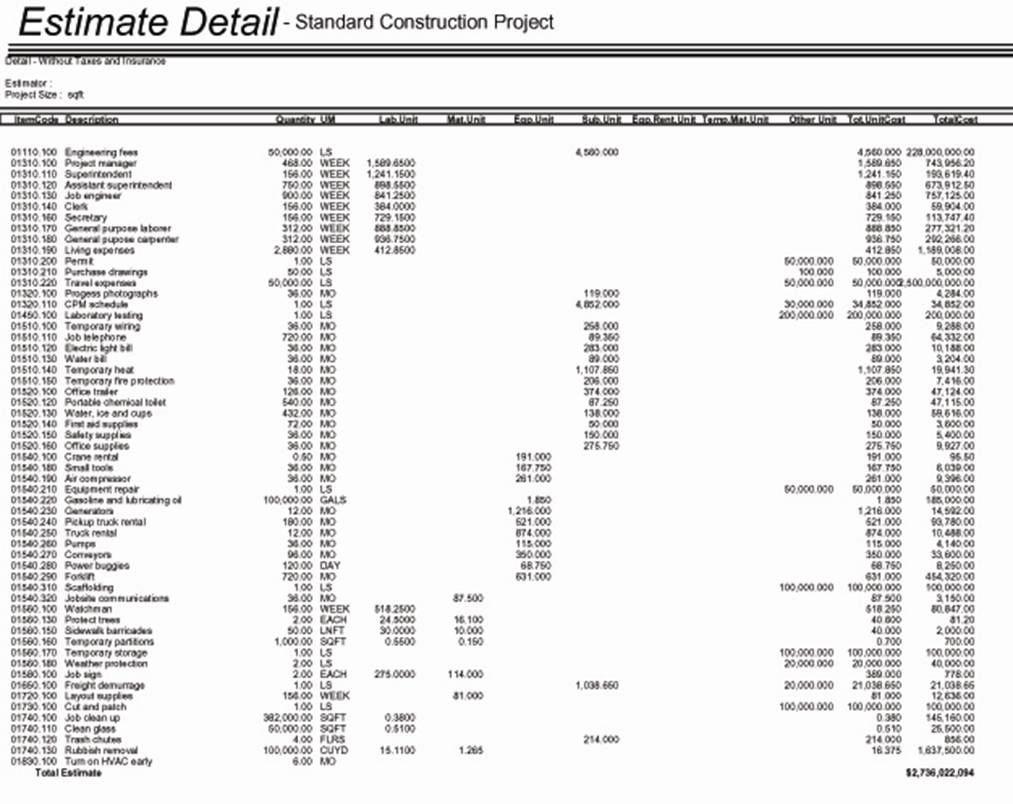

Alternate

System and Methods Analysis

·

Detailed

Systems Estimate pdf

·

General

Conditions Estimate pdf

·

Research

Analysis Methods pdf

The submission of Technical Assignment

Includes the Site Layout Planning with the three main phases: Excavation, Erection, and Interior work. There are minimal changes between the phases

because the building is a renovation project.

The temporary Utilities are fairly simple because the contractor can use

the existing power, water, etc, while the construction going on. The Contractor does need to coordinate the

switchover from existing to the new utilities in order to maintain

operations. The detailed systems

estimate shows a large variation from the previous two estimates, mainly due to

the unstated assumptions in the square foot and assemblies estimates that the

building project is new construction.

Since the project is a renovation the detailed estimate takes into

account the placement methods needed and therefore bears a higher cost of

installation. The general Conditions

estimate worked out to be approximately 3% of the overall construction

budget. The research and analysis

methods go into detail about the goals and objectives of the research and there

is preliminary version of the survey to be used for the research.

·

Excavation

Site Plan features the Courtyard Excavation work

·

Erection

Site Plan features the Erection Plan for the courtyard structure

·

Interiors

Site Plan features the order of

work throughout the interior of the building

Temporary Utilities

The use of

the utilities required to run the renovation are somewhat unique because the

building is a renovation project. The

specification section covering the use of the existing building states that

when the existing utilities are not available for use, when they are being worked

on and changed over, then the contractor should base their use from the

specification section 1500.

Use

of the Existing Building

The existing building must be

maintained in a weather tight condition.

The use of existing utilities

is allowed until such time as they need to be removed to install new utility

lines or replace the existing lines.

(Coordination of the change over is obviously the responsibility of the

contractor.) Permits must be obtained

from Smithsonian Institution in order to perform welding and cutting, because

the building is historic the owner wants to be aware of all work involving a

potential fire. Tools and equipment

causing vibration must also request permission from SI before doing work due to

the potential damage the vibration can cause to the Historic Building. The chart below shows the limitations on the

equipment to be used in the building.

|

Frequency |

Particle Velocity |

|

1-10 Hz |

6mm/sec |

|

10-40 Hz |

6-13 mm/sec |

|

40 Hz and above |

13 mm/sec |

Temporary Utilities

·

Temporary Utilities

·

Sewers and drainage

·

Water service, metering, and distribution

·

Sanitary facilities, including toilets, wash facilities, and

drinking-water facilities

·

Heating and cooling facilities

·

Ventilation

·

Electric power service

·

Lighting

·

Telephone service

Since the building is very old, there are issues relating to the

different expansion and contraction of materials due to changes in

weather. In order to limit the change in

materials due to the temperature, the building is maintained at a relatively

constant temperature using two (2) 40 ton temporary chillers and two heaters

while it is under construction. The

project has not had to add separate services for electricity, sanitary or storm

drainage. All of those requirements are

running from the buildings existing utility supplies and the systems have been

coordinated so there is a direct switch-over from the old to the new system in

all cases.

Support

Facilities

·

Temporary roads and paving

·

Wash racks

·

Dewatering facilities and drains

·

Project identification and temporary signs

·

Waste disposal facilities

·

Field offices

·

Storage and fabrication sheds

·

Lifts and hoists

·

Temporary elevator usage

·

Temporary stairs

·

Construction aids and miscellaneous services and facilities

Security

and Protection Facilities

·

Environmental protection

·

Stormwater, sediment, and erosion controls control

·

Tree, plant, and animal protection

·

Pest control

·

Site enclosure fence

·

Security enclosure and lockup

·

Barricades, warning signs, and lights

·

Covered walkways

·

Temporary enclosures

·

Temporary partitions

·

Noise control

·

Weather protection

·

Fire protection

·

Existing storm water drains

Environmental

Requirements: Concrete Placement

Cold Weather

concreting:

·

Frozen ground: Do not place

concrete on frozen ground.

·

Do not place concrete when temperature is below 40 degrees F,

except with prior approval of Smithsonian Institution

·

Place concrete in cold weather in accordance with ACI 306.

Hot Weather

concreting:

·

Do not place concrete when atmospheric conditions endanger quality

of concrete.

·

Place concrete in hot weather in accordance with ACI 305.

·

Cover reinforcing steel with water soaked burlap if necessary to

maintain steel temperature not exceeding ambient air temperature immediately

before

·

embedment in concrete.

·

Use water reducing retarding admixture when concrete temperatures

exceed 80 degrees F or other adverse placing conditions, as approved by COTR.

At time of

placement, provide concrete temperature not lower than 50 degrees F, or higher

than 90 degrees F. Maintain surfaces receiving concrete at approximately same

temperature as concrete being placed.

Detailed Estimate Takeoff Notes

for Concrete

Below

is shown the Concrete Takeoff for the courtyard. Concrete is used in several capacities. Obviously the slab on grade is concrete, the

elevated slab is also concrete, though only half is structural two way while

the other half is supported on steel beams.

The walls are structural concrete, 18” thick, and half of the columns in

the Courtyard are also concrete.

|

Item |

Dimension |

Quantity |

|

CIP Columns |

14'

Tall, 15" square |

35 |

|

Steel Columns |

18'

Tall, 48 plf |

24 |

|

Steel Columns |

18'

Tall, 58 plf |

5 |

|

One Way Slab |

30'

x 6' |

1 |

|

|

200'

x 7' |

1 |

|

|

20'

x 40' |

1 |

|

|

53'

x 16 |

1 |

|

Total |

|

3250 SF |

|

Two Way Slab |

80'

x 43' |

1 |

|

|

53'

x 3' |

1 |

|

|

33'

x 6' |

1 |

|

Total |

|

3800 SF |

|

Slab on Grade |

|

7050 SF |

|

W shape Beams &

Girders |

3250

SF |

1 |

|

CIP Walls |

18'

x 53' |

2 |

|

|

18'

x 16' |

1 |

|

|

14'

x 75' |

2 |

|

|

14'

x 53' |

1 |

|

Total |

|

5000 SF |

|

Concrete

Columns (#) |

Dimension

1 (in) |

Dimension

2(in) |

Height

(ft) |

CY |

|

24 |

16 |

16 |

14 |

22.12 |

|

4 |

14 |

24 |

14 |

4.84 |

|

1 |

30 |

30 |

14 |

3.24 |

|

7 |

30 |

30 |

18 |

29.17 |

|

Total |

|

|

|

65 |

|

|

|

|

|

|

|

Concrete

Slabs |

SF

area |

Depth

(ft) |

CY |

|

|

SOG East Half |

3800 |

0.42 |

58.64 |

|

|

SOG West Half |

3250 |

0.67 |

80.25 |

|

|

Elev Slab East Half |

3800 |

0.83 |

117.28 |

|

|

Elev Slab West Half |

3250 |

0.67 |

80.25 |

|

|

Total |

|

|

370 |

|

|

|

|

|

|

|

|

Concrete

Walls |

SF

area |

Depth

(ft) |

CY |

|

|

|

5000 |

1.5 |

306 |

|

|

|

|

|

|

|

|

Total Amount

of Concrete |

|

|

741 |

CY |

Detailed Estimate Takeoff Notes

for Steel

Below

is the takeoff of the Courtyard’s steel structural system. Steel is used for the columns and beams in the Auditorium area of

the courtyard which makes up a little less than half of the courtyard

area.

|

Steel Member |

Quantity |

Length (ft) |

Total Length (ft) |

Weight (lb) |

Weight (Tons) |

|

|

Columns |

|

|

|

|

|

|

|

W 12 x |

87 |

10 |

18 |

180 |

15660 |

8 |

|

W 12 x |

120 |

18 |

18 |

324 |

38880 |

20 |

|

|

|

|

|

|

|

|

|

Beams |

|

|

|

|

|

|

|

W 12 x |

26 |

3 |

8 |

24 |

624 |

1 |

|

W 14 x |

26 |

5 |

8 |

40 |

1040 |

1 |

|

W 16 x |

26 |

4 |

10 |

40 |

1040 |

1 |

|

W 18 x |

35 |

3 |

18 |

54 |

1890 |

1 |

|

W 21 x |

50 |

5 |

13 |

65 |

3250 |

2 |

|

W 24 x |

62 |

14 |

18 |

252 |

15624 |

8 |

|

W 30 x |

116 |

2 |

30 |

60 |

6960 |

4 |

|

W 30 x |

99 |

4 |

12 |

48 |

4752 |

3 |

|

W 38 x |

120 |

9 |

64 |

576 |

69120 |

35 |

|

|

|

|

|

|

Total

Weight |

84 |

There is a large change in the cost of the

structural system from the previous estimates.

In reviewing the differences I feel the reason for the increase in this

estimate is the disparity of using the two separate structural systems has come

out. There is an inherent efficiency in

using a single system for an entire structure.

By using two different systems for the east and west halves of the

courtyard structure, there is an increased cost and increased time to

construct. Also, the fact that the

courtyard is in the interior of a building being renovated was more evident

because the placement methods for the steel and the concrete now were taken

into account. In the square foot and