Acid Attack - Case Studies

A. Barceloneta Trunk Sewer (Baceloneta, Puerto Rico) (ACI 210.1R-94, 1996)

B. Los Angeles Sanitary Sewer System and Hyperion Sewage Treatment

Facility (ACI 210.1R-94)

The sewer system of Los Angeles consists of over 6000 miles of sewers

servicing an area of 600 square miles. Two upstream reclamation plants, the D.C. Tillman

and the Los Angeles-Glendale plants serve the San Fernando Valley. These plants treat

sewage to advanced secondary standards discharging effluent into the Los Angeles river and

returning the solids back to the sewers for transport to the Hyperion regional treatment

plant located on the cost of Santa Monica Bay. All other sewers connect to one of four

major interceptors for sewage transportation to the Hyperion treatment plant.

The life span of concrete sanitary sewers in Los Angeles are severely

shortened due to the bacterial acid attack. Long distances traveled to reach the Hyperion

plant cause influent to remain in the sewers up to 72 hours. Point source control of toxin

producing industry has also served to aggravate the existing situation. Previously

produced toxins were directly fed into the sewer systems and actually help reduce the

growth of H2S producing bacteria. With the EPA requirement to pre-treat plant

effluent the toxin levels in the sewer decreased causing an increased growth of the

destructive bacteria and an accelerated deterioration of the concrete sewers (Fig. 1 and

Fig. 2). These unprotected pipes exposed to an increasingly aggressive acid environment

have failed within 5 years.

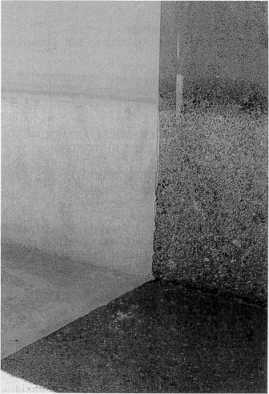

Fig 1. Los Angeles Sanitary Sewer System. Deterioration of concrete pipe from acid H2S attack. |

Fig 2. Los Angeles Sanitary Sewer System. Deterioration of reinforced concrete structures from acid attack. |

For all new concrete construction, protect the inside of manholes and the inside crown of pipes above the waterline with a sheet of acid-resistant PVC, mechanically anchored to the concrete.

For the repair of old concrete construction, restore the concrete surface and then protect it with an applied coating or lining. Current methods used to protect concrete include the application of roll-on plastic sheets which are cemented to the concrete. Spray-on coatings are not considered a long term solution

For existing concrete above the waterline, remove damaged concrete back to sound concrete and restore the surface with shotcrete. Some bad experiences have been found with spray-on coatings , resulting from pinhole holidays and poor quality control (Fig. 3). Roll on plastic sheets have been used successfully, but the physical situation in sewers often prohibits their use.

For new construction above the waterline, provide 100 percent protection using PVC lining systems.

Fig 3. Hyperion Sewage Treatment facility - reinforced concrete sedimentation tank showing coating failure and corrosion. |

C. DWORSHAK NATIONAL FISH HATCHERY(ACI 210.1R-94, 1996)

| Parameter | Value |

Unit |

| pH | 6.5 - 7.4 |

--- |

| Total Dissolved Solids | 28-33 |

mg/L |

| Specific Conductivity | 23-29 |

*mhos |

| Hardness | 12-15 |

mg/L |

| Alkalinity | 15-20 |

mg/L |

| Chlorides | 0.2-0.4 |

mg/L |

| Sulfates | 2.0 |

mg/L |

| Nitrates | 0.07 |

mg/L |

| Sodium | 1.44 |

mg/L |

| Potassium | 0.55 |

mg/L |

| Calcium | 3.75 |

mg/L |

| Magnesium | 0.70 |

mg/L |

Fig 4. Dowrshak National Fish hatchery. Deterioration of concrete surface of tank. Note repaired area to the left of the photograph. |