Welcome to Cynthia Milinichik's AE Senior Thesis e-Portfolio

General Building Data:

Building Name:

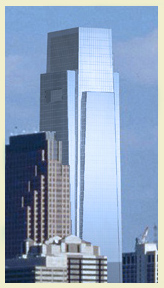

- Comcast Center

- Formerly One Pennsylvania Plaza

Location & Site:

- Philadelphia, PA

- 1701 John F. Kennedy Blvd.

- Other Bordering Streets

- Arch Street, North 17th Street

Building Main Occupant Name:

- Comcast Corporation

- Cable TV

Occupancy:

- Office

- Retail

- Restaurant

Size:

- 1.6M SF Total

- 1,200,000 SF of Office Space

- 23,000 SF Restaurant & Retail

- Site Area: 90,000 SF

Height:

- 57 Stories

- 55 Stories Above Grade

- 1 Mechanical/Office Floor Below Grade

- 3 Parking Floors Below Grade

- 975 ft (297 m)

- 30ft taller than the One Liberty Place, the current tallest building in Philadelphia

Project Team:

- Owner:

- Liberty Property Philadelphia Limited Partnership IV East

- Construction Manager:

- L. F. Driscoll Co.

- Design Architect:

- Robert A. M. Stern Architects

- Architect of Record

- Kendall Heaton Associates

- Structural Engineer

- Thorton Thomasetti

- MEP Designer:

- Paul H. Yeomans

- Landscape Design:

- Olin Partnership

- Civil Engineers

- Pennoni Associates

- Window Washing and Building Maintenance Systems Consultant

- Highrise Systems, Inc.

- Building Acoustics Consultant

- Cerami & Associates, Inc.

- Building Security Consultant

- HMA Consulting, Inc.

- Lighting Consultant

- Quentin Thomas Associates, Inc.

- Owner’s Underground Engineering Consultant

- Haley & Aldrich, Inc.

Construction Dates:

- January 2005 - Fall 2007

Actual Cost:

- $435 Million

Project Delivery Method:

- Design Build

Architecture:

Design and Functional Components:

- Tallest LEED Certified Building in US upon completion

- Glass Façade

- Crown at Top of Building with Dramatic Lighting at Night

- European Style Tower

- Original Design complimented the Philly Museum of Art

- 110’ High Winter Garden w/ Interior Dining Court

- Half-Acre Public Plaza along JFK Boulevard

- Tall-Story Core and Shell High-rise Office Building

Major National Model Code(s):

- ASHRAE

- ANSI

- ASME

- UL

- NEMA

- AMCA

- NFPA

- ARI

- ACI

- ASTM

- NEC

- CRSI

Zoning:

- (still researching)

Historical Requirements/Information:

- Located above railway station

- As part of the project a new grand entrance to the Suburban Station will be constructed

Building Envelope:

- Glass Curtain Wall with lightly tinted, high performance Low-E glass

- Shadow Box Aesthetic around Spandrel Locations

System Descriptions:

Structural System

The Comcast Center has a central concrete core. Steel beams frame into the concrete core with shear connections and are supported by steel columns along the perimeter of the building. Composite concrete slabs on 3” Grade 33 metal deck make up the floor system. Three-quarter inch diameter shear studs are used to transfer forces between the concrete slab and steel members. Lightweight concrete with a weight of 115 PCF and a 28 day strength of 4 ksi is used for the composite concrete slabs. Slab depths range from 6-8 inches. The typical bay for an office type loading is 45 feet long by 30 feet wide with beams spanning 45 feet every 10 feet. The girders are all spandrel girders and are typically W18x40s. The beams are typically W18x35s or W18x40s. Vierendeel trusses are used in certain areas to allow for large open spaces on floors below by diverting large column loads to other columns. The walls of the concrete core act as shear wall to resist lateral loads such as wind and seismic. Caissons penetrate 6 feet into solid rock to ensure adequate bearing capacity. The top of the tower is crowned with a glass clad steel box which is supported by braced steel frames.

Mechanical System

Multiple HVAC systems are used throughout the Comcast Center. The local utility provides steam which is piped to coils, converters and chillers. The steam condensate system includes coolers, traps and controls. Some of the equipment used includes a 1015 ton steam driven absorption chiller and 900 to 2300 ton electric driven centrifugal water cooled chillers with variable frequency drive. The variable air volume system includes 43 air handling units ranging in size from 810-90,000 cubic feet per minute. Entry areas are conditioned with water source heat pumps.