Building Statistics

General Building Data:

Building Name: Clandestine Laboratory Training Center

Location/Site: Quantico Marine Corps Base, Quantico, VA

Building Occupant: Drug Enforcement Agency Training Academy

Occupancy and Function Types:

The building contains spaces of numerous function types including the following:

Two classrooms, a multi-purpose room, an analytical lab with chemical and lab storage, a mock lab, Firearms Training System (F.A.T.S.) facility, a physical training room, a smoke-filled room, chemical clothing and equipment try-on rooms, a raid training facility, a conference room, a break room, administrative offices, and a glass-wash facility. Supplementary spaces include laundry facilities, showers/restrooms, storage, mechanical and electrical spaces, and an outdoor obstacle area.

Size: 34,152 sq ft

Number of Stories: One story plus Mechanical Mezzanine Level

Dates of Construction: October, 2006 – December, 2007 (tentative)

Cost: $10 million (available construction funds)

Project Delivery Method: Invitational Bid for GMP

Project Team:

Owner: United States Navy

General Contractor: unknown, still in bid period

Construction Manager: unknown, still in bid period

A/E Firm: Kling – Architecture, Engineering, Interiors, Planning

2000 L St., NW, Suite 215

Washington, DC 20036

Consultants:

Site/Civil Engineer: A. Morton Thomas

12750 Twinbrook Pkwy

Rockville, MD 20852

7921 Jones Branch Dr., Suite 550

McLean, VA 22102-3306

Acoustical: ACENTECH

33 Moulton St.

Cambridge, MA 02138

Architecture:

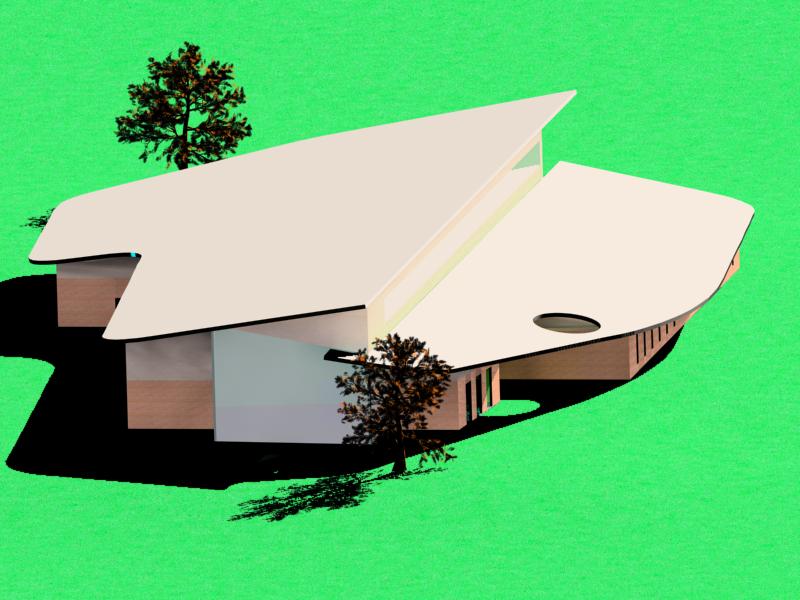

The Clandestine Laboratory Training Center is a one-story (plus a mechanical mezzanine level), slab-on-grade masonry building designed to be aesthetically compatible with neighboring buildings on the DEA Training Academy campus. By utilizing materials such as the brick, concrete masonry, metal panels, and glazing similar to those already employed on campus, the Laboratory Training Center complements adjacent buildings, but still manages to retain its individuality.

One of the most notable architectural features of the building is the curved outline of its metal roof which forms deep overhanging canopies. Because of the building’s relatively low profile, these projections add elements of depth and shadow that are quite evident, while also providing weather protection at entrances. Another prominent feature is a strip of clerestory windows that spans almost the entire length of the west elevation. This stretch of windows is broken in a few places by relief louvers of the same height, flush with the windows to minimize the interruption of the strip effect.

Due to the sloped roof, ceiling heights vary from space to space, with some exterior areas being full-height. Located in an exterior zone, the analytical lab utilizes the generous space between the roof and a drop-ceiling for its extensive exhaust ductwork. Progressing inward, nearing where the roof reaches its peak, a mechanical mezzanine level resides 12’ above the first floor. The raid facility is a full-height space with an observatory catwalk 10’ above the first floor level.

At the northeast corner of the building, the main entrance opens into a lobby which supplies access to the central corridor. Another entrance in the middle of the east elevation also provides access to this corridor, creating a U-shaped circulation system off of which the majority of spaces can be reached.

Building Envelope:

Roof System:

The roof employs a standing seam metal system with 5” of rigid insulation on a 1½” metal deck. Its two 2:12 slopes are offset to allow 6’ clerestory windows overlooking a main interior corridor. In a few locations, relief louvers of the same height are aligned flush with the clerestories. The roof slopes terminate at a curved steel channel painted to match the metal roof.

Exterior Wall:

A brick masonry veneer backed by concrete masonry and 2” of rigid insulation constitutes the majority of the exterior wall system. This is accented by courses of CMU and large curtain-wall expanses of glazing with aluminum mullions which allow natural light to enter the corridors. Much of the wall under the eaves and in the clerestory section is comprised of metal panels backed either by concrete masonry or 6” cold-formed metal studs with 2’ of rigid insulation.

Major National Model Codes:

- NAVFAC Washington A/E Guide, September 14, 2004

- Virginia Department of Transportation Standards and Specifications

- Uniform Facilities Criteria 2005

- IBC 2003

- NFPA 101, Life Safety Code, 2003

- IMC 2003 in conjunction with Military Handbook 1003/3

- Uniform Federal Accessibility Standards

- Americans with Disabilities Guidelines

- Anti-Terrorism Force Protection

Zoning:

Per IBC 302.3.1, Non-separated Mixed Occupancy, Construction Type II-B for Use-Group B-Business and A-3 Assembly

Building Systems:

Mechanical:

Heating: Two 1,500 MBH water tube boilers supply 180°F hot water for space heating as well as for heating of domestic and laboratory hot water via a plate and frame heat exchanger. The heating hot water is distributed via two parallel inline centrifugal pumps in a variable-primary arrangement to the air handling units for primary heating; to unit heaters, cabinet unit heaters, and finned-tube radiators for auxiliary heating; and also to VAV terminal units for reheat.

Cooling: A chilled water system meets the vast majority of the cooling needs. Chilled water of 30% propylene glycol concentration is cooled via two 105.5 ton chillers. The chillers contain air-cooled condensers, so they are located in the utility yard in order to reject heat to the outside. Both chillers contain six hermetic scroll compressors that are electrically driven and handle one step of compression each. The refrigerant specified is R407C. Chilled water leaves the evaporator at 45°F, and is sent via two base-mounted centrifugal pumps in parallel to the cooling coils in the air handling units. Like the heating hot water system, the chilled water system also makes use of a variable-primary pumping configuration. Direct-expansion air conditioning units cool the LAN and electric closets with specially conditioned transfer air. Like the chillers, the ACU’s compressors are electrical and the condensers, remote from the evaporators, are air-cooled.

Air Handling Units: Five air handling units located in the Mechanical Mezzanine Level supply the building with conditioned air. AHU’s 1 through 5 serve Classrooms, the Analytical Lab, Offices, Raid Facility, and Smokehouse, respectively. AHU-2 is a 100% OA unit serving the labs, and AHU’s 1 and 3 are capable of economizer mode. Return air is routed back to the AHU’s through the plenum using transfer ducts and some longer duct runs where necessary.

Electrical:

The building is served via (2) parallel 13.2 kV utility feeders. The 750 kVA main transformer steps incoming power down to 480V to serve the 1,200 A main distribution panel. Emergency power is provided by a 230 kW outdoor generator that is driven by fuel oil.

Structural:

Foundation: Concrete strip footings provide the base along the exterior walls. Square spread footings ranging from 4 to 12 sq ft support exterior and interior columns.

Ground Floor: The 6” slab on grade is reinforced with 6x6 welded wire fabric. The slab was poured on a vapor retarder atop 6” of compacted porous fill over compacted subgrade. A grid of control joints isolates the slab around each column.

Superstructure: Typical steel columns are W10x33 or 39, with the largest ranging up to W10x60. These extend all the way to the roof at varying heights. Diagonal HSS 8x8x3/8 steel tube columns on the exterior provide support of the roof canopy. The Mechanical Mezzanine is framed by beams ranging from W12x14 to W16x31, supported by girders from W14x22 to W24x76. The typical bay size is 34’x28’. The typical size of roof framing members is W16x26, but others range from W12x14 up to W21x44. Girders supporting the roof range from W18x35 to W27x84. The curved outline of the roof is formed by MC 13x40 steel channels.

Lateral Force Resisting System: The building primarily makes use of a braced-frame system, especially on exterior walls, with tubes from 4”x4” to 7”x7” providing lateral support. Moment-frame connections are used in some places on the interior.

David M. Potchak

David M. Potchak