Welcome to Peter Schneck's AE Senior Thesis e-Portfolio

Building Statistics

Building Name: Wesley A. Brown Field House

Location and Site: United States Naval Academy Annapolis, Maryland

Building Occupant Name: NAVFAC

Occupancy and Function Type:

Multi-sport athletic facility

Size (Total Square Feet): 124,000 sqft

Number of Stories: 2 stories and a penthouse

Primary Project Team:

Owner- NAVFAC (www.navfac.navy.mil)

General Contractor- Hensel Phelps Construction Company (www.henselphelps.com)

Architect on Record- HKS Inc. (www.hksinc.com)

Associate Architect- Shalom Baranes Associates (www.sbaranes.com)

Mechanical Engineer- Kavocs Whitney & Associates

Electrical Design- M.C. Dean (www.mcdean.com)

Structural Engineer- Thornton Tomasetti Group (www.thettgroup.DecembeMay 6, 2007p; &nMay 6, 2007May 6, 2007p; May 2006 – March 2008

Actual Cost Info: $45.5 million (project cost)

Project Delivery Method: Design-Build

Architecture

Architecture:

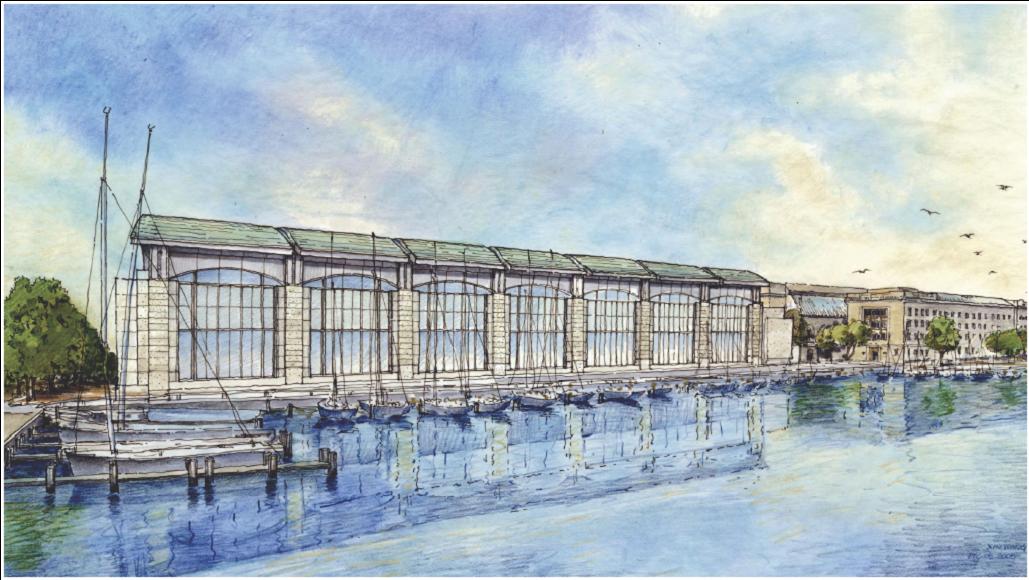

The Wesley A. Brown Field House was first and foremost designed to be an indoor training, support, and event space for various sports. The field house has a 6-lane 200m track that has hydraulically-actuated banked curves which will retract to sit flush with the surrounding surface. The track infield will contain 8 sprint lanes, two long jump/triple jump pits, and 2 pole-vault pits. At the east end of the field house a roll-out 160’ by 360’ turf football field system will be mounted and stored, so that the field house can be transformed into a training facility for the Naval Academy’s Sprint Football team. Also, included in the field house will be 3 basketball courts, 3 tennis courts, 2 batting cages, and 3 volleyball courts. The Field house is located with a view of the Santee Basin. The architects designed the field house with a nautical theme, with a curved roof system that is reminiscent of a sail. There are large curtainwall windows on the North side of the field house that provide a view of the basin and allowing for a large amount of daylight to enter.

Major National Codes:

Building Code: IBC 2003 excluding chapter 10

Life Safety: NFPA 101 2003

Accessibility: UFAS and ADAAG

Zoning:

C2

Building Envelope:

The Building envelope is mainly a Precast Concrete system with punched windows. There are nine types of precast panels, ranging in thickness from 6” to 15”, and varying in texture from a smooth to a textured finish. There are also some CMU walls that run along the base of the building. A metal panel system can also be seen on the east and south elevations, where the penthouse is located on the flat roof that extends out under the large curved roof structure. The main roof is a PVC curved assembly. The assembly is a 60 mil fully adhered felt-backed PVC membrane roof system with applied raised “standing seam” profiles 3 o.c. The color is a medium to light gray, so that it reminiscent of the slate roofing of the adjacent Bancroft Hall. There is a vapor barrier and the roof sits on a 3” metal deck. The steel columns to support the assembly slope to form the curve of the roof.

Primary Engineering Systems

Construction-

Wesley A. Brown Field House is a Design-build project. Hensel Phelps pre-qualified,

through past performances, along with 3 other competitors to bid the project. Hensel

Phelps along with a team of architects and engineers developed a design and construction

schedule to meet the needs of NAVFAC’s RFP. Hensel Phelps won the job through a best

value selection. The value was determined through past performance,

technical/management factors, subtracting plan, design, and a staffing plan that was

communicated to NAVFAC in an oral presentation. The subcontracting plan was of

particular interest, because the Government required a minimum of 73.7% of the

subcontracting efforts to be small business including; 15.3% SDB, 13.8% WOSB, 3.1%

HUBZone Small Business, and 3% SDVOSB. More credited was given for contractors

who exceeded this target. Hensel Phelps won the bid and holds a Guaranteed Maximum

Price contract

Electrical-

The primary switchgear for Wesley A. Brown Field house is 13.8kV. This feeds 2 main

transformers. The secondary double-ended switchgear is 480/277 volt, 3 phase, 4 wire,

and 60 hertz. The switchgear distributes electricity for the electrical closets and

equipment.

Lighting-

The main field area has pulse start metal halide lighting. The rest of the space is primarily

lit by fluorescent lighting. The emergency and exit lighting is powered by backup

batteries.

Mechanical-

There are two types of mechanical systems in the Wesley A. Brown Field House. One is

a CAV system to condition the field arena and the other is a VAV to condition the other

spaces of the Field house. The CAV system is comprise of 2 42,000 CFM AHU’s. These

units supply low-pressure air to the field space via exposed ductwork. The VAV system

is comprised of 100% return air 12,000 CFM AHU for the lockers, a 16,830 CFM AHU

for the lobby, a 7,850 CFM AHU for the weight training area, a 3,570 CFM AHU for the

treatment area, and a 1,520 CFM AHU for the storage areas. The VAV systems will

supply medium pressure via ceiling mounted diffusers. The return air will be collected

through ceiling mounted air devices.

Structural-

The field house is comprise of two main systems acting together. The first system is a

structural steel system that provides a column free athletic area. The next system is a

structure that will enclose the athletic space.

The structural steel system is mainly comprised of Columns that are space 24.5ft apart

along the north and south of the building. The typical size for these columns are W 360 x

134. These columns support box trusses that span 200ft. The size for a typical main

member of these box trusses are W360 x 72.

The foundation system for Wesley A. Brown Field House consists of 406mm Drilled

Pressure Grouted Displacement Piles. These supported a two-way .25M thick concrete

slab.

The enclosure system is comprised of precast concrete panels. These panels range from

6” in thickness to 15” in thickness.

Secondary Systems

Fire Protection-

The fire protection system is an intergrated system of suppressing fires and notifying the

occupants inside the facility that there is a fire. The suppression system is a wet pipe

automatic sprinkler system that completely covers all area of the field house. The

standpipe system is Class I. There are mounted fire extinguishers placed within recessed

cabinets in the main areas of the building, and surface mounted cabinets are provided in

the support spaces. There is a electrically supervised, addressable intelligent, manual and

automatic, annunciated fire alarm and detection system throughout the facility. Manual

pull stations, duct smoke detectors, heat detectors, audio/visual alarms, fire alarms radio

transmitter and electrical supervision of all sprinkler system alarm and supervisory

devices are included in the fire alarm system

Transportation-

There are 3 elevators in Wesley A. Brown Field House. All are hydraulically operated.

There are 2 passenger elevators, one located by the lobby and the other in the middle of

the south elevation of the building, with two stops. The 3rd elevator is a freight elevator

with two stops, located on the west side of the building in the loading dock area.

Telecommunications-

The communications system will be provided from the on campus network system

facility. The voice and data services and Category V services are available throughout the

building. An intercom system is in the Field Area and Weight Training area.

Hydraulic Banked Track-

A six lane 200m hydraulically banked track is to be installed in the Wesley A. Brown

Field House. The track requires a bearing capacity of 500 kg/sqm in the lowered position,

200 kg/sqm in the raised position. The track is manufactured by “Mondo” and is made up

of a steel frame supported by steel beams. The frame fitted with a 21mm thick plywood

with a resin coat. There is a two-layer track surface that is fixed to the plywood with

adhesive. Automated cylinders operated from a computer system provide progression of

the curve at all angles. The track, when not inclined needs to sit flush with its

surroundings.

Synthetic Surface System-

A roll-out synthetic football field is located at the east end of the Field House. The field

will consist of synthetic turf knitted using nylon and a 5/8” shock pad. The field will be

able to cover the field house floor without being labor intensive. Hydraulic driven

winches will help pull the field into proper position. Air blowers with electric drives are

required for pneumatic lift for lifting and lowering the field into its storage pit. The field

meets all football and soccer playing requirements and takes no longer than 2 hours to

roll-out and no more the 1 hour to place back into its storage pit.