Building Statistics Part II

Structural System:

Foundation Systems/ Soils Condition:

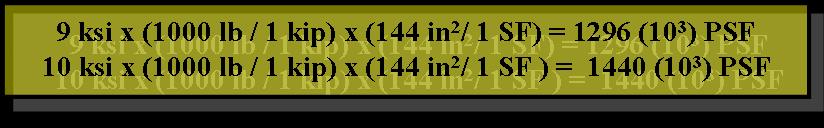

Highly suitable soil was encountered during sub-surface exploration of the Sears Centre site. The soil report specifies a maximum net allowable soil bearing pressure ranging from 3,000 to 4,000 pounds per square foot (PSF). Several boring sa

mples (15’-0” to 30’-0” depth) have recording soil bearing pressures in the gravel, stiff clay and sand region on the order of 3,000 to 4,000 pounds per square inch (psi).

Bearing Pressures for bedrock beneath site soils are as follows:

Deep Foundations:

Soil has been excavated in preparation for the 24’-0” deep foundation walls. Walls of this depth have extreme amounts of lateral pressure caused by adjacent earth. In certain circumstances one option is to construct the foundation walls with a thickness of 33”, it has been determined that this option is neither financially nor physically feasible. 55’-0” long tie backs with an angle of entry 10° will be utilize in the main shoring system to support lateral earth pressure. This solution will enable foundation wall thickness to decrease by 64% resulting in a wall thickness of 12.”

(Flooring Systems-Footings-Piers-Foundation Walls)

• Design for 4,000 PSF

5” thick SOG for main lobby and concourse level.

Superstructure:

The main concourse framing primary consist of a system

of 10” pre-cast hollow core planks, pre-cast beams, raker beams and

rises. Pre-cast planks for the general assembly floors are accompanied with

a 2” concrete topping. Horizontal structural members, are

comprised of pre-cast concrete and range in size variation from 12” x

24” to 30” x 42” square configuration. Raker beams which

provide load transference to the pre-cast columns were employed for structural

support of the arena bowl. Typical raker beam sizes used

in project construction are 18” x 24” and 18” x 36”.

Beams with the smaller depths were used in the construction of the seating

mid spans Beams with deeper depths were used for the lower seating levels.

Pre-cast vertical members range from 12” x 12”, 16”

x 16”, and 18” x 18” to 24” x 24”.

Structural Steel framing assemblies are used on the bridge and suite level. The steel

structural system for the upper arena areas comprises of a series of W 10

– W 30 beams with varying sub weight. Bowed W 18 x 40 beams are used

along the south side of the arena bridge level as part of the framing system

for the Suite floor system.

W 14 and W 10 beams form the upper and lower chords of the truss system

that supports the TPO/ EPDM Roof. These beams are joined by W 14 steel angles

to form the complete truss assembly.

Mechanical Systems:

The Sears Centre Arena/ Concourse/ Suite and Common areas HVAC system is designed to supply air at a rate of 240,000 cfm. The main HVAC system is a 70/30, adjustable/ variable volume system that consist of (6) 40,000 cfm (28,000 cfm Outdoor Air) Air Handling Units located in the Northeast and Southeast roof top mechanical rooms. Each AHU is constructed of 2” thick double insulated metal wall panels.

AHU Assembly/ Components

• Mixing Section (Outdoor air and return air dampers)

• Heating Coil

• 30% + 85% filters

• Chilled H20 Coil

• Centrifugal Supply Fan with VFD

• Supply Duct Silencers

Supply air is distributed to the Arena bowl and event level via (5) 66” Ø un-insulated spiral duct. Operation tolerance restricted circular duct location to be at least 8” above the roof truss bottom chord. The air distribution system is designed to maintain 75° F/ dry bulb 50% relative humidity, (70° F/ dry bulb 50% relative humidity for ice events) during year long operations. Main air supply lines for the arena bowl have supply duct “off-shoots” that accommodate 40/20 supply diffuser size. (6) 40,000 cfm return air units are located at the perimeter of arena along the mechanical catwalk.

Administrative and Ticketing facilities are served by

(1) 20 Ton Roof VAV unit sized for 10 VAV zones. The north and south lobby

air distribution system is composed of (2) 15-ton constant volume single

zone RTU(s) supplying air @ 6,000 cfm. The Heating Water System for the

Sears Centre consist of (2) 10,000 MBH gas-fired flexible tube water boilers.

VFD water pumps are cable of delivering 180°F water supply to all air

handling units, perimeter VAV boxes, misc. heaters and domestic water supplies.

The chilled water system consist of (2) 600 ton electric drive centrifugal

chillers, expansion tanks, air separators and (2) 600-ton VFD fan control

cooling towers with (2) chilled water pumps sized to provide chilled water

for 1,200 gpm.

Electrical/ Lighting Systems:

The main power service and distribution for the Sears

Centre consist of a 277/480 Volt 3-Ø, 4-wire supply service. Secondary

power distribution has been sized for 120/208 Volt supply. (2) Step-down

utility service transformers provides the initial 480 Volt 3-phase, 4-wire

service @ 3,000 amps. The electrical spaces on the event level houses (8)

transformers ranging is size from 30 KVA to 500 KVA. (2) 500 KVA transformers

provide service to (2) 1600 amp panel boards which in turn each feeds (4)

800, 600, 400 and 60 amp panels respectively. One 300 KVA transformer serves

a dedicated 600 amp service panel which will provide power for mechanical

equipment and mobile television truck connections.

Six deferent luminary fixture schemes were used in high density areas. The

main lobby employed the use of 60”, 42” and 30” diameter

decorative pendant fixtures with compact fluorescent lamps @ 277 Volts.

Arena offices and conferences room lighting systems are comprised of 2’0”

x 4’0” recessed direct/ indirect fluorescent fixtures with T-8

lamps running on a 277 Voltage. Concourse areas are lighted with linear

fluorescent fixtures with (2) twin 4’-0” T-8 (835) lamps per

fixture. The seating bowl contains a lighted hand rail that is illuminated

with 3W LED(s). Arena concession areas provide lighting by means of recessed

fluorescent down lights. The auxiliary lighting system for the catwalk level

is a system composed of quartz floodlights in a strip fixture configuration,

at a system voltage supply of 120/208 V.

Plumbing/ Fire Protection Systems:

Domestic cold water is sized for a peak 45,000 gpd use

(~ 12,600 gpd average for 200 days). The domestic cold water supply is by

means of 8” diameter water main routed via the northeast corner of

the event level. Cold water distribution, in addition to domestic water

service, provides irrigation water service, cold water fixture connections

i.e. (food concession-kitchen areas), and make up water w/ backflow prevention

to heating water, chilled water and condenser water systems.

Domestic hot water service is designed to provide 140° F water distribution

by means of (2) 1,500 gallon, 3,000 gph indirect fired storage water to

water heaters. A triplex water booster system will be used as the catalyst

to facility water movement into the upper arena areas.

The Sears Centre uses a hydraulic designed wet sprinkler fire suppression

system. Wet sprinkler systems are not required in the arena bowl for floor

to roof deck distances less than 25’-0”. In addition to the

wet sprinkler system, the Sears Centre fire suppression system is integrated

into the building controls and zone hazard annunciation-smoke detection

system.

Section 1024.6.2.3- Fire Protection

• Fire Sprinklers are required in all areas

• Exception (1) When ceiling is < 50’-0” above floor level and the use is restricted to low fire hazards.

Conveying Systems:

The Sears Center Conveying system is composed of (2) different types of elevator systems. The electric traction elevator operates on a 480-V, 3 Ø 60 cycle system. This electric traction elevator has a net weight restriction of 3,500 lbs and a minimum speed of 200 ft/ min. The elevator shaft extends from the depth of the event level to the height of the roof catwalk. The hydraulic elevator utilizes the same power system for its motor and hydraulic pumping unit. (2) of the (3) elevators in the Sears Centre will have a rated capacity of 3,000 lbs and employ the use of this electo-hydraulic pump system.

Ice-Rink System:

Ice-Rink Design Criteria

The Sears Centre will contain an 85’- 0” wide by 200’- 0” long, 28’-0” edge radii ice rank design to serve events sized for a 9,000 patron seat configuration. Rink perimeter slab provisions are (86’-2” x 201’-2” with a 28’-7” edge radii for a ± 3/16” tolerance for the 20” rink edge.). Ice-rink ambient temperatures are designed for a 70° F/ dry bulb 50° F dew point temperature 48” above the ice surface. Broadcast lighting at the arena event level of ice events is will be provided @ 250 foot candles. The Ice Rink System consist of under floor heating and cooling headers and pipes, pipe chairs and valve boxes essential to ice production and maintenance. (2) 4” lifts of clean compacted sand will interact with H2O in ice production prior to ice performances and events. A 6”, 5,000 psi reinforced concrete slab will supply the structural support for the arena event level/ ice-rink.

Integral Ice-Rink System Components

• Compressors

• Oil Return System

• Brine Chiller

• Evaporative Cooler

• Condenser Water Spray Pumps

• Brine Heater

• Snow Melt Pit Coil

• Quick Ice-Take-Out Heat Exchanger

• Rink Floor Cold Brine Pumps

• Under floor and Snow Melt Pit Warm Brine Pumps

• Glycol (Jacket Cooling) Pump

• Expansion and Mixing Tanks

• Refrigerant and Piping Accessories

• Brine and Water Piping Accessories

• Gauges and Thermometers

• Rink Cooling Floor Pipe Chairs

• Rink Floor Valve Boxes

• Refrigeration Control Panel

• Refrigeration DDC Control System

• Refrigeration Gas Detector

• Self Contained Breathing Apparatus

• Ice Re-surfacer Water Demineralization System