Welcome to Ming Norman Tsui's AE Senior Thesis e-Portfolio

Building Statistics

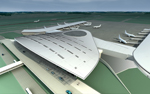

Indianapolis International Airport

New Midfield Terminal

Part I

General Building Data

Building Name: Indianapolis International Airport – New Midfield Terminal

Location & Site: 2349 Aviation Drive , Indianapolis , Indiana 46241

Building Occupants: Indianapolis Airport Authority

Function Type: Airport, Transportation Hub

Size; 1,200,000 Square Feet (1.2 Million Sq.ft)

Total Level; 5 Stories + Roof

Project Team

Owner: Indianapolis Airport Authority

Design Architect: Hellmuth, Obata + Kassabaum. Inc. ( www.hok.com )

Architect of Record: AeroDesign Group ( www.aerodesigngroup.com )

General Contractor: A Joint Venture of Hung Construction & Smoot Construction LLC.

CM: A Joint Venture of Turner Construction & Trotter Construction

Structural: Thornton-Tomasetti Engineers ( www.thettgroup.com )

MEP: Syska Hennessy ( www.syska.com )

Fire Protection: Syska Hennessy

Lighting: Hellmuth Obata+Kassabaum, HOK Lighting Group

Construction Date: 2005 - 2008

Overall Project Cost: $975 millions

Delivery Method: Design-Bid-Build

Architecture:

Architecture: The heart of the new terminal will be a circular space – reminiscent of downtown's Monument Circle – that also features two nearly identical concourses A and B, which have 20 gates each. The central portion of the terminal connecting both concourses will house baggage screening, baggage claim, retail, and some 96 check-in counters and 18 passenger screening checkpoints.

Major National Code: ASHRAE/IES 90.1- 1999 Energy Code.

Zoning: Occupies approximately 7,700 acres (about 12 square miles) .

Building Envelope: The terminal design is dominated by its great, arched roof, which will shelter the glass walls from the sun and collect the sun's illumination through its skylights. The arching will promote natural cooling by harnessing the airflow over its surfaces and the roof surface will reflect energy, limit heat gain and channel water for collection. The terminal is has utilized a unitized glazed slope curtainwall system as the building skin all around the every façade. For support, architectural steel truss and steel tube framing are mainly used for the support of the covering roof.

Part II

Building Systems

Mechanical System: Release of information is not yet approved due to security purposes

Electrical System: Release of information is not yet approved due to security purposes

Fire Protection: Waiting for consultants approval of drawings and response.

Transportation: Vertical and horizontal transportations are distributed throughout the two concourse for servicing. By building the terminal in the “midfield” between the main runways, taxiing will be cut significantly, reducing passengers' time spent in aircraft, as well as fuel consumption, air pollution and noise.

Structural: Some 4,815 tons of asphalt and 2,433 tons of concrete from existing pavement has been rubbleized and reused as fill for the terminal project. The terminal is has utilized a unitized glazed slope curtain wall system as the building skin all around the every façade. The arching roof is supported by an array of steel tube frames, columns, and truss with special aluminum coating spanning every 28 feet. The perimeter of the roof is wrapped around with insulated aluminum composite panel systems. To top it off, a 7”insulated membrane roof covers the entire undulated roof.

Lighting: The majority of the lighting system is rated for 277V operation. The Civic Plaza and concourse rely extensively on skylight and daylight harvesting throughout the day. General concourse spaces lighting utilizes downlights with compact fluorescent lamps. Certain office space has features linear fixtures with florescent lamps. Specialty low voltage lighting 120/12V and incandescent lighting will be used individually within retail spaces, conference rooms and certain cafeteria spaces for accent purposes. Exterior/entry façade flood lighting and civic plaza accent lighting is all 277V luminaries with metal halide lamps. In compliance to LEED, the new terminal will release the minimum amount of light pollution to the night sky.

Construction: The construction delivery method for this building was design-bid-build. In 2002, the Indiana Department of Transportation (INDOT) breaks ground on a project to relocate a portion of Interstate 70 in conjunction with airport construction. The $187 million INDOT project includes a dedicated I-70 interchange to serve the new airport and a new Six Points Road at I-70 interchange. By July 2005, The Indianapolis Airport Authority and local officials break ground on construction of the new airport passenger terminal building. It is slated for completion by late 2008. In compliance to the new USGBC's LEED Certification, u sing regional (within a 500-mile radius) materials in the construction and local and regional plants in the landscaping are just some of the aspects of the project.