Welcome to Adam Weis's AE Senior Thesis e-Portfolio

Wilke-Barre Scranton International Airport Statistics

• Building Name: Wilkes-Barre/Scranton International Airport

• Location and Site: 100 Terminal Road, Avoca, PA

• Building Occupants: United, USAir, Delta, Continental, Northwest,

Car Rentals, and Concessionaires

• Occupancy Type: Airport

• Size: 127,000 SF

• Number of Stories Above Grade: 2

• Total Height: 35 feet

• Dates of Construction: September 18, 2003 – December 3, 2005

• Overall Project Costs: $30,000,000.00

• Project Delivery Method: CM Agency

Primary Project Team

• Owner/Developer – Bi-County

Board of Commissioners (Luzerne /Lackawanna Counties)

• Construction Manager –

Turner Construction -

www.turnerconstruction.com

• Architects – HNTB Architecture

- www.hntb.com

• Engineers

-Civil

– Highland Associates - www.highlandassociates.com

- Structural

– Highland Associates / Pasonick - N/A

- MEP

– Highland Associates

• Consultants

- Testing/Inspection

– Applied Geo Sciences and Engineering - N/A

- Acoustic

– Holler and Metzger - www.hellerandmetzger.com

- Signage

– Apple Designs -

www.appledesigns.net

- Security

– Glover Resnick and Associates - www.glover-resnick.com

- Data/Communication

– Ross and Baruzzini - www.rossbar.com

Architecture

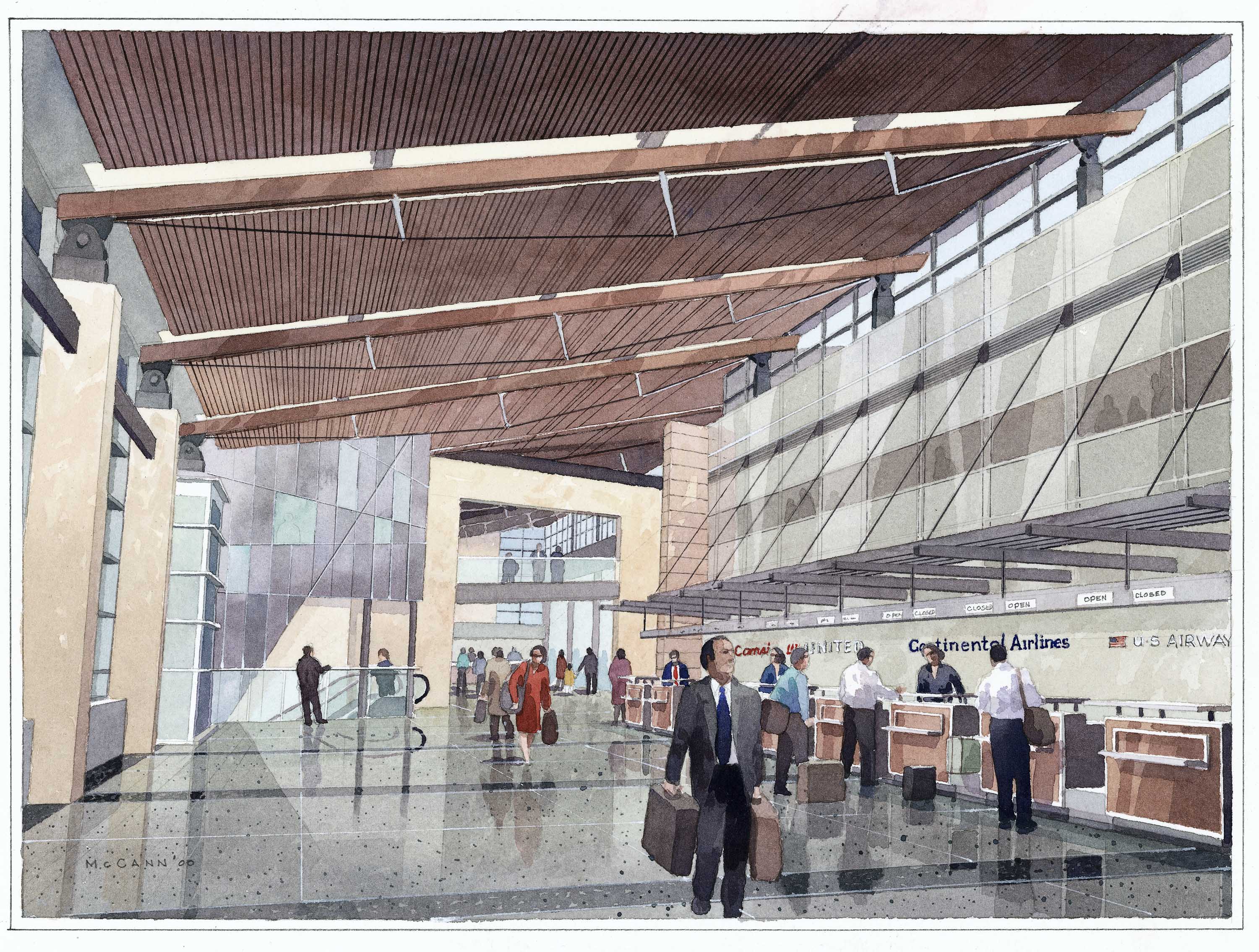

• Architecture – The airport foot print is

in the shape of a “T” with the base of the “T” at

an angle. The entrance from the parking deck starts you out in a tunnel

or cave like entrance. As you ascend the escalators you are dumped into

the spacious  ticketing

and baggage section of the airport. The feeling is created by many of Frank

Lloyd Wright’s houses where there is a cramped room or hall that leads

to a more open larger room. This gives you a feeling of suspense as you

can see the large area at the top of the escalators. Large open spaces in

the ticketing and baggage claim give flyers the feeling that they are in

a large airport as well. Starting at the tunnel entrance there is split

face sandstone block, as you proceed along the airport you will notice the

cuts of sandstone progressively get smoother until you reach the terminals

where the sand stone is polished. This effect is supposed to give a feeling

that you are leaving a cave. (Hence the underground entrance) There are

many windows and store fronts throughout the airport for commuters, as well

as their friends and family, to look out over the Luzerne and Lackawanna

Valley or watch the air traffic or pretty scenery. This is nice since the

airport is located on the top of the valley. There is also a unique “meditation”

area for flyers to meditate, pray or just have some quiet time before their

flight, located right in the middle of the building front.

ticketing

and baggage section of the airport. The feeling is created by many of Frank

Lloyd Wright’s houses where there is a cramped room or hall that leads

to a more open larger room. This gives you a feeling of suspense as you

can see the large area at the top of the escalators. Large open spaces in

the ticketing and baggage claim give flyers the feeling that they are in

a large airport as well. Starting at the tunnel entrance there is split

face sandstone block, as you proceed along the airport you will notice the

cuts of sandstone progressively get smoother until you reach the terminals

where the sand stone is polished. This effect is supposed to give a feeling

that you are leaving a cave. (Hence the underground entrance) There are

many windows and store fronts throughout the airport for commuters, as well

as their friends and family, to look out over the Luzerne and Lackawanna

Valley or watch the air traffic or pretty scenery. This is nice since the

airport is located on the top of the valley. There is also a unique “meditation”

area for flyers to meditate, pray or just have some quiet time before their

flight, located right in the middle of the building front.

• Major National Codes – This airport was built

according to the codes and standards of the FAA, as well as the following

additional codes: the BOCA 96, PA Code Title 34 of 1998 and the 1990 ADA.

• Zoning – Airport

• Historical Info – There is

no historical value to this site.

• Building Envelope – The building is enclosed with metal panes and a glass curtain wall system. the glass is double glaszed and is UV rated to prevent to much of the sun's rays for entering. In some areas of the airport the glazing has white lines to block out the suns rays. These windows are located on the south facing side of the building. The roof is composed of elastomeric membrane that is bonded directly to the roof surface. The flat roofs of the building have this membrane while sheet metal roofing is found in areas where the roof slopes.

Primary Building Systems

• Electrical/Lighting – The lighting and electrical

systems enclosed in this airport are not unlike many others throughout the

country. Direct recessed lighting fixtures are found throughout the airport.

The switch gear is composed of two 1500KVA transformers which break the

incoming power down into 480/277V lines. There is a 2000A 10-port tie-in

off of each transformer that routes the power throughout the building. This

provides extra power to run the six passenger boarding bridges as well as

the baggage check and baggage claim belts in the building. The building

and tarmac have additional generators to power emergency lighting, runway

lights and the control  tower

in case of a power failure. In addition to that, generators also have enough

power to run all of the outlets, lights, and anything else that would need

power in the airport. The building is fully loaded off

this system in case of power outage.

tower

in case of a power failure. In addition to that, generators also have enough

power to run all of the outlets, lights, and anything else that would need

power in the airport. The building is fully loaded off

this system in case of power outage.

• Mechanical – Because this building

serves as an airport, the mechanical system is very important. Placing the

AHU on the roof is important; so as to avoid drawing in too much of the

air surrounding the concourse — filtering out the jet exhaust is very

critical. The system is composed of 12 rooftop units which condition the

air. Backing up those units there are nine VAV boxes situated throughout

the airport. Two boilers supply the airport with hot water for cleaning

or heating purposes. There are also two rooftop condensers used to help

with the air conditioning needs. There are exterior unit heaters that will

be used in the breezeways and commuter terminals; these heaters will need

to have unit heaters on the lines to prevent them from freezing in the winter.

• Structural – The structural feature of the Wilkes-Barre/Scranton International Airport include mostly spread footings with steel columns. Much of the sub-grade foundation work is made of pre-cast concrete elements. About 80 percent of the building is 6” slab on grade with #4 reinforcement spaced 16” apart. The other 20 percent is made up of composite flooring at grade level. The high roof areas of the airport have complete open spaces with large cable steel trusses spanning the width of the baggage claim and ticket circulation. The columns supporting these trusses are W12x58 encased in pre-cast architectural concrete on the low end and W14x90 or W10x45 supporting the higher end. There is also a large architectural sandstone wall the runs through the entire building, supported by a variety of W14 columns. The second level of the airport is composed of composite flooring.

Secondary Building Systems

• Fire Protection – The sprinkler system is

a standard wet pipe setup. There are a few outdoor sprinklers located in

breezeways and commuter gates; these sprinklers are dry lines because of

the cold winters typical in northeastern Pennsylvania. All of the main structural

members have spray-on fireproofing where needed. In some areas there is

exposed steel; that steel will be treated with intumescent paint. Non-visible

members will be enclosed or out of sight.

• Conveyance – Several people

movers are installed throughout this building. There are a total of six

escalators, three personal elevators and one freight elevator. In addition

to all of these, there are six passenger boarding bridges to get people

from their gate onto their plane without having to face the elements. There

are also the conveyors that move the people’s luggage. There is a

simple conveyor loop that brings the bags out to the baggage claim. A similar

one is used for baggage check, but this conveyer lacks a return.

• Telecommunication – The communication

system in this airport is very important. The building will need to be tied

into the old control tower to relay information about flights to the airport.

The building will also act as a semi-business center, so the airport is

equipped with many lines out, as well as Wi-Fi connection for computer usage.