Welcome to Tim Mueller's AE Senior Thesis e-Portfolio

Building Statistics

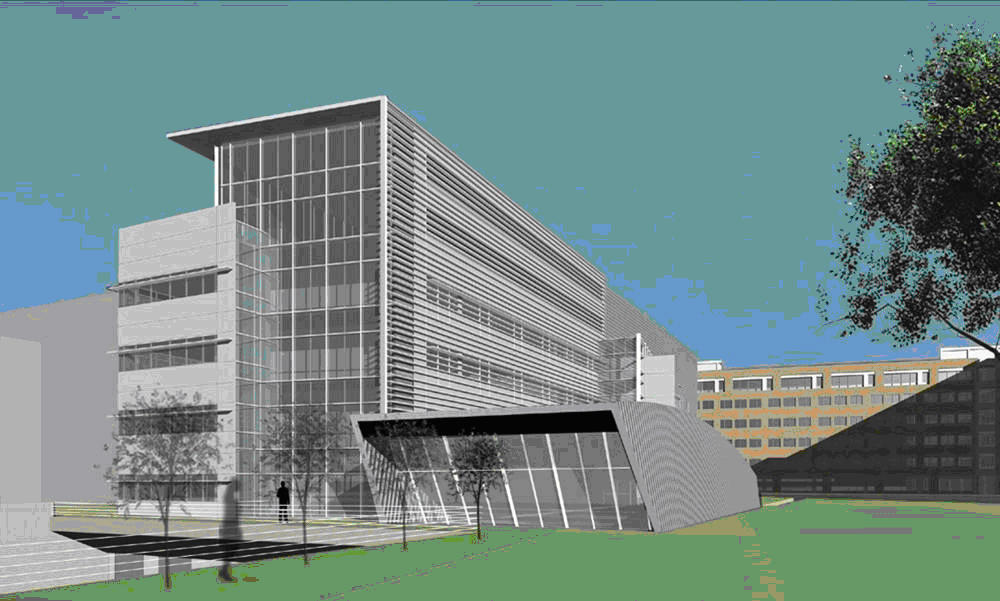

The FDA-CDRH Laboratory is being built on the U.S. Food and Drug Administration's White Oak Consolidation Campus In Silver Spring, Maryland. The main building is office and laboratory space with the focal area being a large high-bay laboratory on the west side of the building. It is constucted using a cast-in-place one-way concrete system with a steel framed roof. The exterior is made predominately of sheet metal, aluminum, and large glazed panels, with hoizontal sunshields.

Below is a more indepth look at what really makes up the CDRH Laboratory.

General Building Data

Building Name:

• FDA-CDRH Physics Laboratory

Location and site:

• 10903 New Hampshire Ave.

Silver Spring, Maryland 20903

Building Occupant Name:

• United States Food and Drug Administration

Occupancy or function types (type of building):

• Laboratory and office

Size (total square feet):

• 139,805 square feet

Number of stories above grade / total levels:

• Four (4) stories above grade

• One (1) ground floor below grade

• 5th floor penthouse suite

Architect, Engineers, and Contractors or CM:

• Architect: Kling in association

with RTKL

• Structural Engineer: Kling

• MEP: RTKL

• Interiors: Kling

• Site: Civil & Environmental: Greenhorne

& O’Mara

• Owner: GSA

• GC: Tompkins

Construction, subsidiary of Turner

• CM: Heerey-Tishman

• Lighting Contractor: Truland

• Mechanical Contractor:

John J. Kirlin

• Concrete Contractor: Miller

and Long

Dates of construction (start – finish):

• March 22, 2005 – November 1, 2006

Actual cost information (Overall project cost):

• $63 million

Project delivery method:

• Design-bid-build

Architecture

Architecture (design and functional components):

• The main CDRH laboratory building has a five-story central core

with the top story being reserved for the penthouse suite, and a four-story

section on the east side. The main entrance to the building is centered

on the east side while the delivery and ground level entrance is on the

north side. The below grade ground floor though the fourth floor are combined

office and laboratory space. The perimeter is mainly single offices with

the central areas being used for laboratories. There is also a large high

bay laboratory, with larger equipment including an anechoic chamber, which

is capped with a decorative curved roof on the west side of the building.

Major national model code/s:

• GSA Facilities Standards for the Public Building Service, PBS-PQ1001.1

as revised June 1996

• International Building Code, IBC 2000 (chapter 10, means of egress

excluded)

• NEFPA 101, life safety code, LSC 2000 for means of egress

• Maryland building performance standards, as amended October 2001

• Americans with Disabilities Act (ADA) and Uniform Federal Accessibility

Standards (UFSA)

Zoning:

• Zoning was not a pertinent issue for the CDRH laboratory do to the

fact that the entire property is owned by GSA. An EIS had to be done in

the beginning of the consolidation for all construction projects and needed

to be approved by the National Capital Park & Planning Commission.

Historical requirement of building or zone where built:

• The CDRH laboratory is being built on the former US Navy facility

at the Federal Research Center – Naval Ordinance Laboratory. This

site was completely cleared prior to the beginning of Phase 1 of the FDA

Consolidation; the CDRH building is part of the Phase 3 construction plan.

For historical purposes, one original building, the entrance building, will

remain on site and will be completely renovated. The new buildings will

have a style that is not traditional to the site.

Building Envelope:

• Roof: There are four levels to the roof system found at

the CDRH laboratory. The first is a planted roof that is at grade over a

section of the ground floor. It is assembled as follows: concrete deck,

water proofing membrane, protection sheet, root barrier, rigid insulation,

drainage mat, filter fabric, and soil. Also on this section is a paved roof

system that is assembled as follows: concrete deck, water proofing membrane,

protection sheet, rigid insulation, filter fabric, pedestal, and pavers.

The second level is a sheet metal roof assembly that is over the specialized

high bay laboratory space. It is assembled as follows: acoustic metal deck,

sheathing, vapor retarder, rigid insulation, “z” furring, plywood

sheeting, underlayment, and standing seam metal panel. The third roof system

is over the fourth floor, this system is termed as the main building’s

low roof and is made up an inverted roof assembly. It is assembled as follows:

metal deck, concrete deck, waterproofing membrane, protection sheet, rigid

insulation, filter fabric, and stone ballast. The fourth level is over the

penthouse suite and is termed as the main buildings high roof. It is also

made up of the inverted roof assembly.

• North Elevation: This elevation can be viewed in the rendering

below. This is the only elevation open to the ground floor. It starts out

with a solid appearance with a cast stone exterior on the ground floor.

The central section is an aluminum window curtain wall that is completely

glazing and aluminum mullions. The central area is flanked on the east by

a four-story, more traditional layout, metal panel and aluminum ribbon window

curtain wall. This wall also includes sun screens made of thin aluminum

strips placed on the upper quadrant of the windows. You can also see the

north side of the specialized laboratory space which is made by a curved

roof over an aluminum panel curtain wall. This same aluminum paneling is

used throughout the laboratory on all secondary design elements. This is

also the elevation from which you can view the vegetated retaining wall.

• East Elevation: This elevation has a large background of

the five-story central area made completely out of horizontal flush mounted

metal paneling. The background is broken up by a multitude of sunshields

on the south end of the building made to look like horizontal mullions running

half the length of the building. In the foreground of this elevation is

a three tear façade, the center of which is the most predominate

tear in which larger rectilinear sections of aluminum paneling was used.

This is flanked on both sides by an aluminum curtain wall made to have a

very horizontal feel by using a design of thin strips of the same paneling.

The final tear is made of the more traditional looking metal paneling/aluminum

ribbon window as seen in the north section.

• South Elevation: Similar to the north elevation, the south

elevation has a 5 story central area made completely out of a glazed curtain

wall with aluminum mullions. East of the central core of this is the four-story,

more traditional looking aluminum and ribbon window design with sun shields.

You can also see the lower edge of the specialized laboratory with its aluminum

curtain wall and curved sheet metal roof.

• West elevation: This is the most diverse façade,

and can also be seen in the rendering below. As with the east elevation,

the west has a broken backdrop with the north end having a formed metal

panel given a horizontal look with a waved corrugation pattern. In the foreground

of this section is once again the traditional aluminum paneling and ribbon

window curtain wall with sunshields. Below this you can see five skylights

protruding out of the green roof, to light the hallways below. On the south

end of the building is a five-story aluminum curtain wall that is completely

covered with sun shields to give an extremely horizontal feel. Also in this

section are three balconies serving the second through fourth floor. These

balconies act as a central focus point on this side of the building. With

the use of cast-in-place concrete, they are given a very rigid and enduring

look. This section also uses the same aluminum windows that are seen throughout

the building, and flush metal panels. Finally the main view of the artistic

sheet metal roof over the specialized high bay laboratory can be seen completely.

At the base of the curved roof is stone base giving it a felling of importance

and grandeur.

Primary Engineering Systems

Construction (means and methods, special systems, expanded

contract info, general items not covered in other engineering categories,

etc.):

• The construction of the CDRH laboratory had to coincide with two

other elements. One was an underground service tunnel that needed to be

knocked into once the foundation excavation was completed. The other was

a bridge that would be built to connect the laboratory to the neighboring

office building. The site is very large, thus leaving ample space for construction

trailers as well as parking for laborers and administration. Also, all roads

into the site, at the present time, are existing roads from the former functions

of the site. New road construction and traffic patterns will be managed

after the completion of this phase and do not pertain to this job. The crane

was located near the entrance to the site, making delivery of equipment

and supplies that needed to be brought in on crane very easy. The site demolition

and preparation was minimal due to the multitude of new construction occurring

on site. The building excavation included slopped sides to avoid collapse,

and a base of at least 760mm below finish grade. The entry into the excavation

pit was originally located on the north end of the building due to the grading

requirements of the finished job (the lower level is to be accessible from

the north end). Over the course of the project this hole in the excavation

will be transformed into a loading dock for supplies for construction and

then the finished building. The CDRH laboratory is also a sustainable or

“green” building and is trying to obtain a LEED rating of silver.

Electrical:

• The electrical system in all the buildings on the consolidation

site is supplied by the CUP (Central Utility Plant). There are two substations

found in the CDRH Lab, designated North and South. Each substation has 13.8KV

primary feeder from the CUP. That is converted from 3000/3990 KVA to 480Y/270V.

Due to the use as a laboratory there are many panels found in the building.

All lighting panelboards are found in closet spaces located in three positions

on each floor, North, South, and Cental. While laboratory panelboards can

be accessed from the labs and hallways for safety purposes. This building

uses both 208/120V and 480Y/270V. There are also specialty transformers

found in the building to supply many unique products such as 380Y/220V lab

equipment and specialty items such as 400Y/230V German Receptacles that

are converted using a rotary frequency converter. Typical receptacles for

the laboratory, such as duplex and 208/120V, can be found either on walls,

prefabricated raceways, or in overhead racks. Each substation services a

300KW boiler on the penthouse floor. Together the substations also service

one fire and jockey pump. The North Substation has one 1600A, 480Y/277V

busduct servicing the ground though fourth floors. The South Substation

feeds three total busducts, one 1600A, 480Y/277V busduct, and two 1000A,

480Y/277V busducts, all servicing the ground thought fourth floors. If there

is an emergency with one substation the other can take over the entire load

in order to continue operation of the lab without setback.

Lighting:

• The main luminaire used in the laboratories and offices of the CDRH

Laboratory is a linear fluorescent troffer. There is also fluorescent under-cabinet

lighting found in laboratory spaces. The typical hallway will either use

a compact fluorescent 127mm diameter downlight or a 159mm incandescent downlight.

Wallwashers found in the areas of the building are the same style as the

local downlights with a wallwashing aperture. 229mm square compact fluorescent

lights are found over cabinetry around the perimeter lab spaces. All industrial

areas such as the penthouse, utility closets, and loading areas have bare

linear fluorescent tubes. The basement lobby has a decorative “skylight”

in which linear fluorescents tubes are placed behind a translucent panel.

The actual skylights found on the ground floor have decorative lights mounted

in out coves in the concrete sidewalls of the skylight. The upper lobby

areas have linear fluorescent cove lighting housed in a decorative stainless

steel soffit. All offices, hallways, and laboratory spaces have motion detecting

occupancy censors. All lights have an emergency version that is equipped

with a battery pack incase of electrical failure. There are lit exit and

sign boxes with statements such as “laser in use” and “dark

room in use” throughout the building. The specialized high bay laboratory

has both high bay industrial 647mm fluorescent and incandescent luminaires.

The emergency lighting in this space is xenon with lead calcium batteries

around the perimeter of the room. The exterior lighting includes step fluorescents,

compact fluorescent downlights, and linear fluorescent strips in architectural

details. The sight lighting has floodlights and post top luminaries lighting

pathways and H.I.D. site pole luminaires for the surrounding areas.

Mechanical:

• Air handling units are all located in the penthouse of the CDRH

Laboratory. Air handling units 1 through 4 supply the main buildings laboratories

and offices for cooling purposes only. There are three cooling coils per

unit. Each of the units can supply 23596cfm while in taking a minimum of

14866cfm outside air. Each unit is equipped with a humidifier and an enthalpy

wheel for conservation of exhausted cooled air. They also have 30% efficient

pre-filters and 95% efficient final filters. Air handling units 5 and 6

are for the north and south stair respectively. Each unit is for heating

and cooling purposes. They can each supply 3851cfm and 4814cfm respectively

and neither need to intake any outside air. The heating for the laboratories

and offices are supplied though two electric steam boilers. The boilers

each have ten steps and a maximum of 30kw per element. They operate at a

pressure of 105KPa and have a capacity of 457Kg/HR steam. The steam is transmitted

into heat though finned tube radiation that are floor and wall mounted throughout

the building. The third floor computer room has its own chilled water cooling

unit with a capacity of 45.7KW and a supply of 3828cfm. There are nine exhaust

fans found in the penthouse, six of which are fume hood exhausts. The remaining

three are for ventilation. There are also multiple fan coil units located

in the service rooms, such as data closets and mechanical rooms. Each space

is equipped with a silencer and a VAV (variable air volume) boxes.

Structural:

• The structure of the CDRH Laboratory, with the exception of the

roofing systems, is typically made of cast-in-place concrete with a one

way slab system. Typically there are stepped footing lining the entire perimeter

of the building with a maximum step depth of 900mm. Spread footings are

located below each of the columns and were typically 6,400mm apart in the

north-south direction, with a verity of separation the east-west direction.

There is a 287KPa bearing minimum required for all footings. The ground

floor is typically either 150mm or 200mm deep slab-on-grade with150X150/MW19XMW19

W.W.F. on 200 porous fill on compacted subgrade. All the poured columns

are 600X400 in one of 6 types. With the typical column on the penthouse

being either W360X122 or W250X73. The typical joist is 254mmX520mm, while

the typical beam can range from 254mmX460mm up to 900mmX792mm. There are

also progressive collapse beams in different exterior wall sections, these

beams are typically 500mmX760mm. The steel beams in the penthouse roof range

from a W360X32.9, W310X21, W250X17.9, to a W200X15. The typical slab is

in the north-south direction with a depth ranging from 115mm to 200mm. The

loading for the building have very specific designations, however office

loading was always taken as equaling that of a corridor, for the ability

to utilize an open floor plan.

Additional Engineering and Engineering Support Systems

Plumbing:

• The CDRH laboratory has one main pump room on the ground floor of

the building. There are a total of 12 pumps. The pumps are used throughout

the building to process the multiple water and gas systems used in the lab.

There are two hot water systems, one for the labs and one for the domestic

hot water. Compressed air, vacuum, and carbon dioxide systems are utilized

in this building. There is also a deionized reverse osmosis water system

also used for supplying the laboratories. Rainwater is diverted out of the

building from the roof to a consolidation campus-wide, central storm drain

collection system.

Fire Protection (active and passive systems as appropriate.

Primary fire construction type as defined by code):

• There is an extensive fire protection plan in the CDRH laboratory,

the main fire alarm control panel (FACP) located on the first floor. This

is also the location of the annuciator panel. All floors are fed from the

FACP to a fire alarm terminal cabinet (FATC) for all of the smoke detectors

and dampers that will be used in the HVAC ductwork. Each floor also has

a power booster from which runs the strobe and speaker warning devices.

There are two standpipes found in the building, one of which also supplies

the buildings sprinkler system. A1892L/min pump brings the water to the

stand pipes. A dry pipe system is used in all areas of the building except

for the high bay area that has a pre-action sprinkler system. The high bay

laboratory does not have fire protection on its exposed structural steel.

All other exposed structural steel will receive and inorganic zinc-rich

primer. The concealed structural steel does not require fireproofing.

Transportation (elevators etc.)

• There are three elevators in the CDRH laboratory, one service and

two passenger elevators. The service elevator services all floors including

the penthouse. While the passenger elevator only services the ground though

fourth floor. The passenger elevators are hoisted with a 30KW drive and

can lift 1600 kilograms at a rate of 1.8 meters per second. The service

elevator is hoisted with a 4080 KW drive and can lift 4080 kilograms at

a rate of 1 meter per second.

Telecommunications:

• The CDRH laboratory has two data closets per floor servicing all

telecommunications on that floor. In the laboratories, telecommunications

are typically mounted below the receptacles in the prefabricated raceways

or on overhead racks. The most typical types of outlet are combination data

voice and fiber optic. The typical office’s main communication outlet

is a wall mounted combination data and voice. A few analog telephone outlets

can still be found in the break rooms. There are also some localized intercoms

between hallways and specialty rooms, such as the darkroom. The most advanced

telecommunications center is the second floor conference room. This space

includes multiple floor mounted devices, an integrated podium, overhead

speaker system, and automatic window shades.

Special Systems:

• Security: Due to the CDRH laboratory’s classification

as a governmental facility, an in-depth analysis of the security system

can not be publicly discussed. However, there are multiple cameras though

out the site connected to a CCTV system, as well all exterior and major

laboratory doors have card readers with either electric strike or magnetic

locks. There are also request to exit passive infra red motion detectors

on many of the doors.

• High Bay Laboratory: The most demanding section of the

CRDH laboratory is the High Bay laboratory. It houses very precise instruments

such as a precision calibration anechoic chamber, a controlled-environment

room (cold room), and MRI chamber. Much of the equipment is housed using

radio-frequency (RF) standalone shielding. There is also a pit section,

for the local transformers, below the basement grade to help control vibration

and interruption. Much of the power supplies had to be encapsulated as to

not allow conductivity.